2026 Best Robotic Palletisers for Efficient Warehouse Automation?

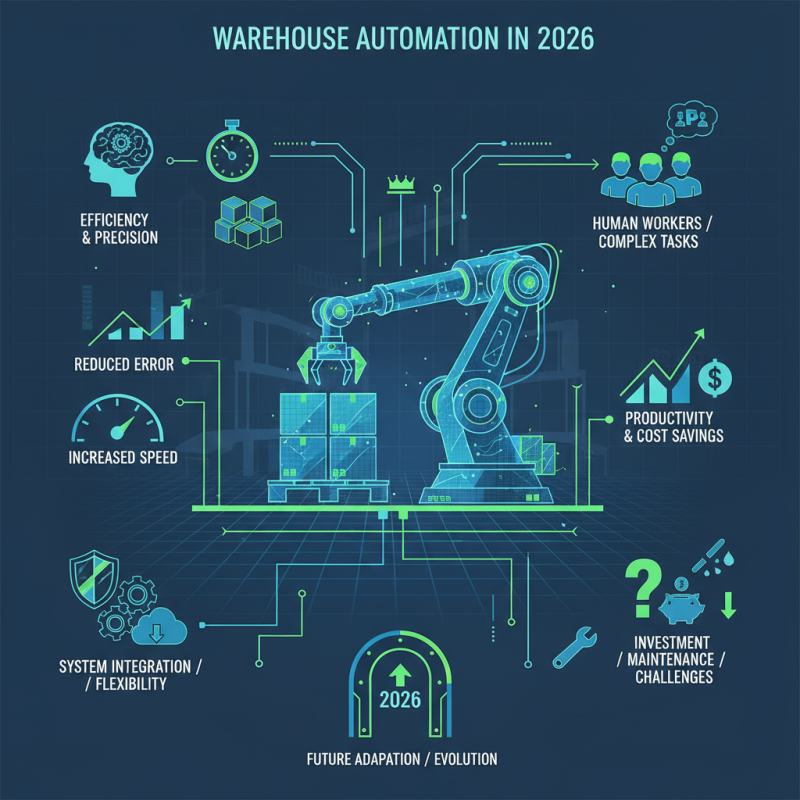

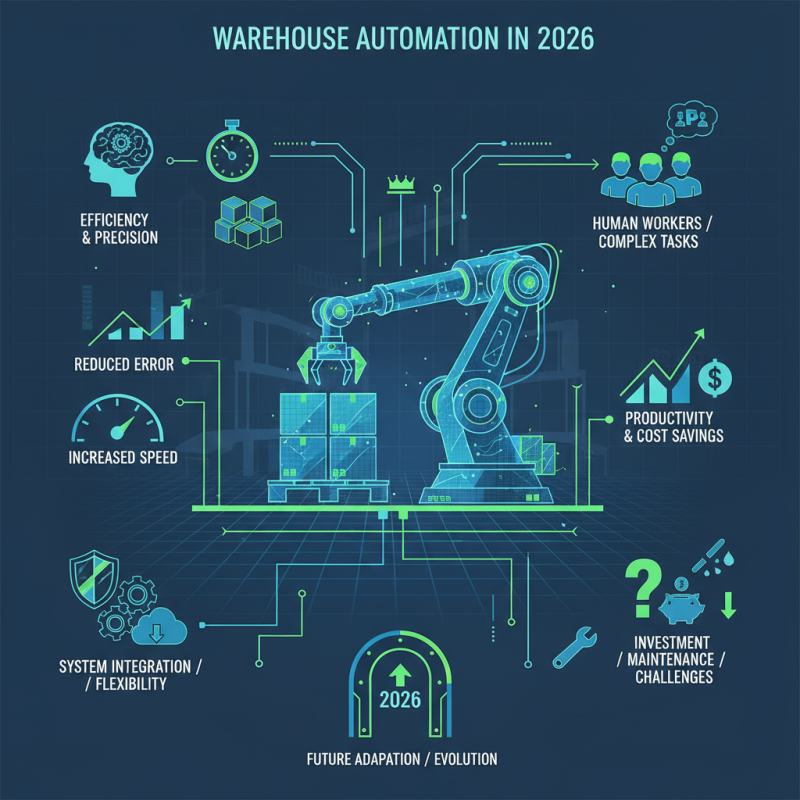

The automation landscape in warehouses is rapidly evolving. Robotic Palletisers are at the forefront of this change. They provide efficiency and precision. These machines handle tasks like stacking and organizing goods. This allows human workers to focus on more complex duties.

Efficiency is vital for productivity. Robotic Palletisers reduce human error. They speed up processes significantly. In a world where time equals money, these systems can make or break a business. However, not all solutions are perfect. Companies must evaluate their specific needs. Choosing the wrong equipment can lead to wasted resources and frustration.

As we look to 2026, the best Robotic Palletisers will need to adapt. They should integrate smoothly with existing systems. Flexibility will be crucial in addressing changing demands. Yet, there are challenges. Significant investment is required. Ongoing maintenance and training are necessary. This journey toward automation is both exciting and uncertain.

Overview of Robotic Palletisers in Warehouse Automation

Robotic palletisers are revolutionizing warehouse automation, offering significant improvements in efficiency and productivity. According to recent industry reports, the global market for robotic palletising is expected to reach $3.1 billion by 2026. This growth is driven by increased demand for automation and the need for improved accuracy in high-speed production environments.

Implementing robotic palletisers can result in a 20% reduction in labor costs. They operate continuously and reduce human error, leading to better accuracy in packaging processes. However, the initial investment may be a barrier for smaller companies. Regular maintenance is essential. Those who overlook this may face downtime, which can negate productivity gains.

When considering robotic palletisers, assess the specific needs of your warehouse. Evaluate your product variety and pallet size requirements. It's vital to select a system that aligns with your operational needs. An effective layout can enhance productivity by 30%.

Tip: Regular training for staff on new technologies will ensure smoother integration of robotic systems. Stay informed about the latest innovations and best practices in the industry. This can help in re-evaluating the chosen automation solutions over time.

Key Features to Look for in Robotic Palletisers

When considering robotic palletisers for warehouse automation, several key features stand out. Speed is paramount; efficient machines can handle up to 1,200 pallets per hour. This statistic underlines the importance of speed in maintaining a seamless workflow. It's vital to choose a system that adapts to various pallet types and weights, ensuring versatility in operations.

Another significant aspect is the ease of integration. Many facilities still use legacy systems. A robotic palletiser must communicate effectively with existing machinery. Data from industry reports suggest that 70% of companies face challenges in integrating new technologies. Thus, having an adaptable interface is essential.

Safety features cannot be overlooked. Robotic systems must come with advanced safety mechanisms to prevent accidents. Contact sensors and emergency shut-off options provide necessary safeguards. Reports indicate that over 30% of workplace injuries are related to equipment. Therefore, investing in safety technology is crucial for a productive environment. These considerations, while beneficial, also present challenges that must be addressed to maximize efficiency in the warehouse.

2026 Best Robotic Palletisers for Efficient Warehouse Automation

Benefits of Implementing Robotic Palletisers in Warehousing

Robotic palletisers are transforming warehouse operations. They automate the stacking and arranging of products on pallets. This greatly reduces manual labor. Workers can now focus on more complex tasks. Moreover, these machines handle products with precision. They minimize damage, which is crucial for maintaining inventory quality.

Implementing robotic palletisers brings various benefits. Firstly, they enhance efficiency in packaging operations. With faster stacking speeds, warehouses can process larger volumes. This boosts overall productivity. Additionally, the systems can work around the clock. However, it's important to consider integration challenges. Training staff to operate these machines can be time-consuming.

Cost is another factor to reflect on. While robotic systems require upfront investment, the return can be significant. Companies see a reduction in operational costs over time. However, it's essential to analyze whether this investment aligns with business goals. Balancing automation and human labor is crucial for future growth.

Future Trends in Robotic Palletisation Technology

The future of robotic palletisation technology is indeed promising. By 2026, industry reports estimate that over 30% of logistics operations will rely on robotic systems. These systems enhance efficiency, reducing labor costs and increasing accuracy in warehouse operations. However, the initial investment remains a barrier for many businesses.

Current trends focus on improved AI and machine learning capabilities. Robots can now adapt to different pallet sizes and handling methods. Reports indicate that 40% of palletising robots are integrating smart technology. Despite these advancements, challenges like maintenance and compatibility with existing systems persist. Many facilities struggle to update their older equipment.

Moreover, safety remains a concern. As robots operate alongside humans, ensuring a secure working environment is critical. Industry analysts suggest that a shocking 20% of robotic implementations face safety compliance issues. Businesses must navigate these complexities to fully realise the potential of robotic palletisers, balancing innovation with practical limitations.

Home

About Us

Products

Stranding & Bunching Machine

Extrusion Lines

Cable Packaging Machine

Automatic Cable Coil Strapping and Shrink Wrapping Machine

Automatic Cable Coiling and Wrapping Machine

Automatic Cable Coiling Machine with Microcomputer Control

Automatic Cable Spooling and Coiling Machine

Automatic Double Coiler

Cartesian Coordinate Palletizer

Circinate Film Cable Coil Automatic Packaging Machine

Film Heat Shrinking Machine

Robotic Palletizer

Auxiliary Equipment

Solution

News

Blog

Contact Us