2026 Best Tubular Stranding Machine for Efficient Cable Production?

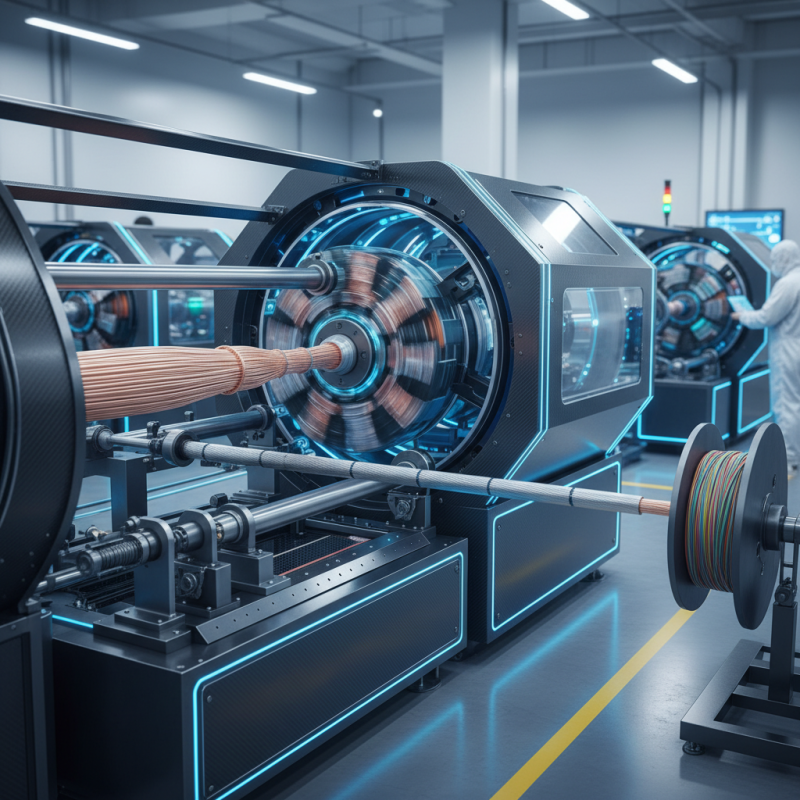

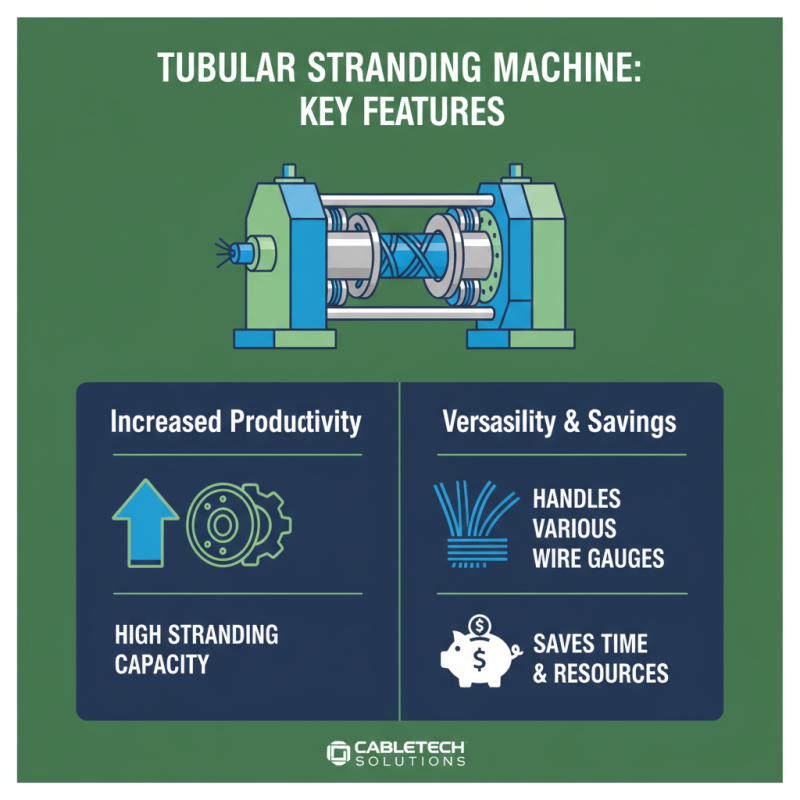

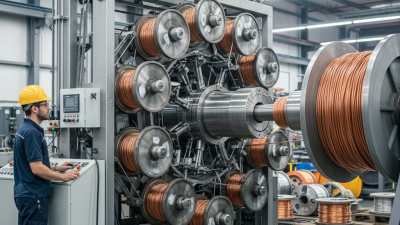

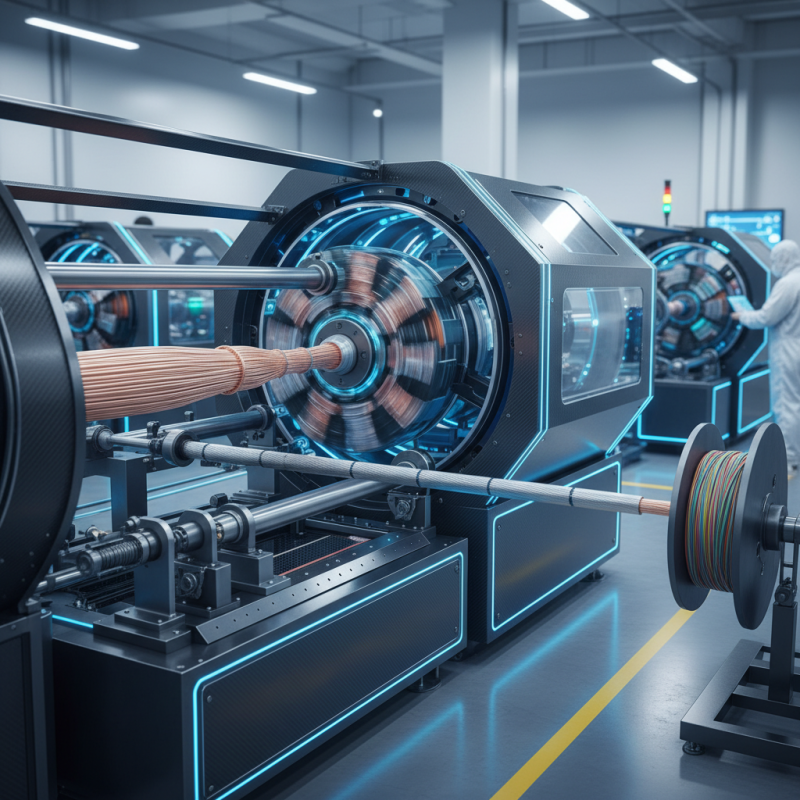

In the fast-evolving world of cable production, efficiency is key. The Tubular Stranding Machine stands out as an essential tool for manufacturers looking to enhance their output. These machines are designed to create high-quality cables with precision. However, selecting the best model for 2026 requires careful consideration.

Modern Tubular Stranding Machines offer advanced features that significantly boost productivity. They can handle various materials and sizes, making them versatile. But, they come with challenges. For instance, understanding maintenance needs is crucial. Failure to do so can lead to costly downtimes.

Moreover, the price of these machines varies widely. It’s important to evaluate long-term benefits against initial investment costs. A well-chosen Tubular Stranding Machine can yield substantial returns. Still, buyers should remain vigilant. The market is filled with options, and not all machines will meet expectations. An informed decision is essential for any successful operation.

Overview of Tubular Stranding Machines

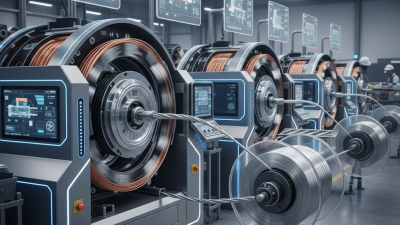

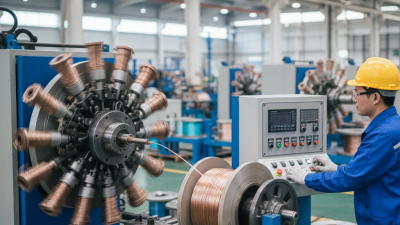

Tubular stranding machines play a significant role in modern cable production. These machines twist together multiple wires to create robust cables. Their efficiency is key to meeting growing demands in various industries. Yet, not all tubular stranding machines are created equal. Some may struggle with precision or speed, impacting overall productivity.

The design of these machines often incorporates advanced technology. Automation features can significantly enhance the stranding process. However, operators must remain vigilant. Issues such as misalignment or inconsistent tension can arise. Such problems might lead to quality defects in the final products. Regular maintenance is crucial but can be overlooked in busy production environments. This highlights the need for continuous improvement in machine operation and training.

In evaluating the best options for 2026, companies must assess their specific needs. Factors like output speed, strand diameter, and ease of operation are vital. Investing in a high-quality machine can yield better returns. However, the cost should be considered against the expected output. Striking a balance between quality and budget is essential for success.

2026 Best Tubular Stranding Machine for Efficient Cable Production

| Model |

Diameter Range (mm) |

Stranding Speed (m/min) |

Number of Bobbins |

Weight (kg) |

Power Consumption (kW) |

| Model A |

1.0 - 4.0 |

300 |

12 |

1500 |

25 |

| Model B |

1.5 - 5.0 |

350 |

16 |

1800 |

30 |

| Model C |

2.0 - 6.0 |

400 |

20 |

2000 |

35 |

| Model D |

2.5 - 7.0 |

450 |

24 |

2200 |

40 |

| Model E |

3.0 - 8.0 |

500 |

32 |

2500 |

45 |

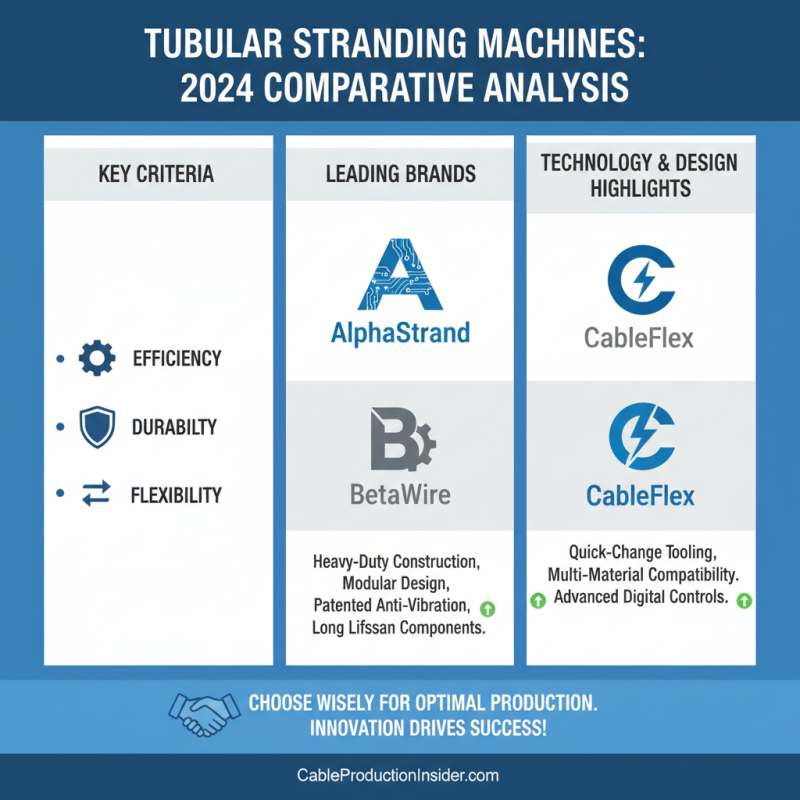

Comparative Analysis of Leading Brands in 2026

In the competitive world of cable production, selecting the right tubular stranding machine is crucial. Efficiency, durability, and flexibility can significantly impact the production process. Various brands offer distinct features that cater to different manufacturing needs. This year, a comparative analysis has revealed notable differences in technology and design.

Machine A stands out with its user-friendly interface, simplifying operator training. However, it does face challenges in handling multiple cable types. Meanwhile, Machine B shows remarkable speed but may compromise on build quality, raising concerns over long-term reliability. These factors highlight the continuous struggle between achieving speed and maintaining durability.

Even the highest-rated machines can disappoint. Regular maintenance can be a headache, affecting productivity. The need for improvement is constant. Manufacturers must remain agile in adapting to the evolving demands of the market. Ultimately, analyzing these machines reveals a landscape full of both innovation and critical gaps, demanding ongoing reflection.

Cost-Effectiveness and Return on Investment Considerations

In the quest for a reliable tubular stranding machine, cost-effectiveness is crucial. Businesses must assess upfront costs alongside potential returns. A more affordable machine may seem enticing, yet low maintenance costs can elevate the total expense. Invest time to find the right balance.

Tips: Consider long-term savings. A durable machine may be pricier but can reduce downtime and repair costs over time. Maintenance schedules should be factored in early. This helps avoid unexpected expenses later.

A wise investment pays off. Look for equipment that offers flexibility and efficiency. It’s important to analyze the machine's performance data. Solid performance directly impacts production output. By evaluating energy usage and operational costs, businesses can find machines that support growth without breaking the bank.

Tips: Ask about warranty and support options. Having reliable after-sales service can save you money. Regular consultations can keep your machine up and running efficiently. Reflect on your operational needs frequently. Adapting to production shifts is essential for staying competitive.

Future Trends in Cable Production Technologies

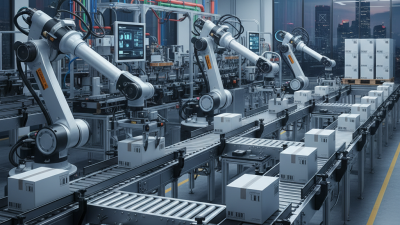

The future of cable production is rapidly evolving. Emerging technologies in tubular stranding machines are reshaping the industry landscape. A recent report indicates that automation in cable production could reduce labor costs by up to 30%. This shift towards automation offers improved efficiency and consistency in manufacturing processes.

As nanotechnology gains traction, it opens doors for more efficient materials in cable production. This could result in lighter and stronger cables. Industry experts noted that the global demand for lightweight cables is projected to grow by 25% in the next five years. However, the integration of these advanced materials poses challenges. Manufacturers may need to rethink existing equipment and methods to accommodate new types.

Sustainability is another key trend. Cable producers are exploring eco-friendly materials, which could lead to reduced environmental impact. Reports show that companies adopting green technologies have seen a 40% increase in customer preference. Despite these promising trends, manufacturers face hurdles in transitioning to greener practices. Balancing cost, efficiency, and sustainability remains a critical concern for the industry.

Home

About Us

Products

Stranding & Bunching Machine

Extrusion Lines

Cable Packaging Machine

Automatic Cable Coil Strapping and Shrink Wrapping Machine

Automatic Cable Coiling and Wrapping Machine

Automatic Cable Coiling Machine with Microcomputer Control

Automatic Cable Spooling and Coiling Machine

Automatic Double Coiler

Cartesian Coordinate Palletizer

Circinate Film Cable Coil Automatic Packaging Machine

Film Heat Shrinking Machine

Robotic Palletizer

Auxiliary Equipment

Solution

News

Blog

Contact Us