Top Automated Packaging Machine Benefits for Your Business?

In today's fast-paced market, efficiency is key. Businesses are recognizing the value of investing in an Automated Packaging Machine. According to a report by Smithers Pira, the global demand for packaging machinery is expected to reach $50 billion by 2025. This trend highlights the growing importance of automation in the sector.

Automated Packaging Machines streamline operations, improving speed and accuracy. They can reduce labor costs by up to 30%, according to industry analysts. Furthermore, these machines enhance product consistency, which is crucial for brand reliability. However, companies need to consider initial investment costs and training for staff.

Despite these challenges, the long-term benefits often outweigh the drawbacks. For instance, automated processes can lead to a 20% increase in productivity. Companies that embrace this technology can stay competitive. Yet some businesses may overlook their unique needs, leading to inefficient implementations. A tailored approach is essential for maximizing the advantages of an Automated Packaging Machine.

Key Advantages of Automated Packaging Machines for Businesses

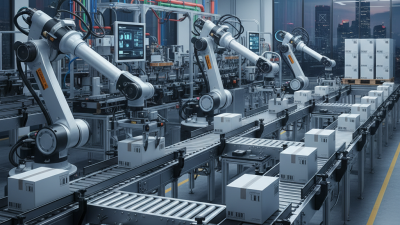

Automated packaging machines offer numerous key advantages that can significantly enhance business operations. These machines streamline the packaging process, reducing the time needed for wrapping, sealing, and labeling products. This efficiency can lead to faster production rates. In turn, it helps businesses meet rising consumer demand. Imagine a busy factory floor where time is money; automated systems can help you keep pace.

Another noteworthy benefit is consistency in packaging quality. With automated machines, the risk of human error decreases. Each product is packaged uniformly, which improves brand presentation. Packaging plays a vital role in customer perception. A well-packaged product can attract more buyers. However, shifting to automation isn't without challenges. Initial investment costs can be high, and staff might resist change.

Training is essential to ensure smooth operation. Employees need time to adjust to new systems. Additionally, regular maintenance is crucial to avoid downtime. No system is perfect. Businesses must continually assess their processes. Considering both the positives and potential hurdles is crucial for effective integration of automated packaging.

Improved Efficiency and Productivity in Packaging Processes

Automated packaging machines bring substantial improvements in efficiency and productivity to businesses. These machines reduce manual labor, ensuring faster packaging. This can lead to higher output rates in a shorter time. Efficiency boosts can lower operational costs significantly. Companies can reallocate labor to more critical tasks.

Tips: Assess your packaging needs carefully. Choose a machine that fits your product specifications. Explore different options before making investments. Efficiency should not compromise quality.

Incorporating automated systems can streamline the entire process. First, they simplify repetitive tasks with speed and precision. Workers experience less fatigue, promoting a better work environment. However, transitioning to automation isn’t flawless. Some machines need frequent calibration. It might take time to train staff adequately. Beware of the initial costs. They can be daunting, but the long-term gains often outweigh them.

Tips: Monitor machine performance regularly. Keep an eye on output rates. Address any discrepancies immediately. Continuous improvements lead to greater efficiency.

Top Automated Packaging Machine Benefits for Your Business

Cost Savings Through Reduced Labor and Material Waste

Automated packaging machines offer significant cost savings for businesses. A recent study by the Packaging Machinery Manufacturers Institute found that automating packaging can reduce labor costs by up to 30%. This is especially crucial for industries facing labor shortages. Automated systems streamline workflows, allowing workers to focus on higher-value tasks.

Material waste is another area where automation shines. Inconsistent packaging processes can lead to excess materials and increased expenses. Research indicates that companies using automated solutions reduce material waste by as much as 10%. Improvements in precision and efficiency minimize errors and ensure optimal use of resources. However, with initial investments required, some businesses hesitate to transition.

Adopting automated packaging technology isn’t without challenges. Companies must ensure their workforce is trained effectively to manage new systems. Inefficient training can lead to problems. Additionally, maintaining and servicing these machines can incur extra costs. Despite these potential setbacks, the long-term savings in labor and materials often outweigh initial concerns. Addressing these issues is critical for maximizing the benefits of automated packaging.

Enhanced Consistency and Quality in Packaged Products

Automated packaging machines bring a leap in consistency and quality for businesses across various sectors. A report from the International Society for Food Technology suggests that 70% of packaged goods now depend on automated solutions. This shift ensures that products are sealed and labeled uniformly, reducing the risks of contamination. With enhanced precision in packaging, businesses can maintain their quality standards.

Research shows that inconsistencies in packaging can lead to up to 30% product returns. Automated solutions mitigate these issues, ensuring that every item is packaged identically. This reliability builds customer trust and satisfaction. However, some companies still rely on manual packing. The transition can seem daunting, even though the benefits are clear. Employees may worry about job security, while management might stress over initial costs.

While automation promises enhanced quality, it requires adjustments. Training staff to operate these machines isn't always straightforward. Errors during the setup can lead to waste. Companies often underestimate the time needed for full integration. Despite these challenges, the long-term gains typically outweigh the hurdles. Adopting automated packaging can lead to significant cost savings and improved product quality over time, shaping a competitive advantage.

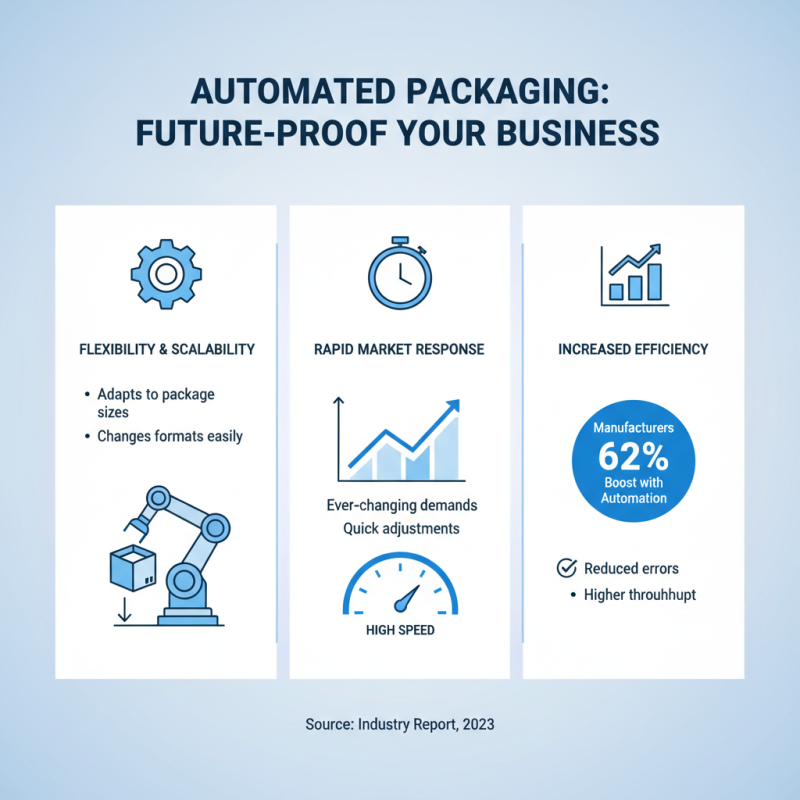

Flexibility and Scalability in Meeting Market Demands

Automated packaging machines offer remarkable flexibility and scalability. Businesses face an ever-changing market, demanding quick responses. According to a recent industry report, 62% of manufacturers noted increased efficiency with automated systems. These machines adapt to different package sizes and formats, responding to varied consumer preferences.

Production lines equipped with automation can scale quickly. For instance, during peak seasons, companies can increase output without extensive downtime. A study by the Packaging Machinery Manufacturers Institute found that companies leveraging automation report a 30% rise in productivity. This ability to pivot is crucial in today’s fast-paced market.

However, embracing automation isn't without challenges. Initial costs can be significant, and technical issues may arise. A surprising 25% of businesses reported disruptions due to integration problems. This highlights the importance of thorough training and support. Businesses must weigh these factors carefully as they consider automated packaging solutions.

Home

About Us

Products

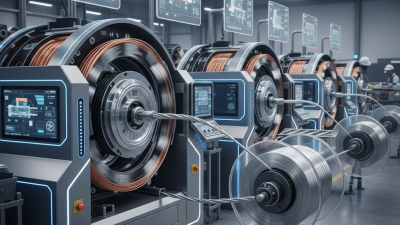

Stranding & Bunching Machine

Extrusion Lines

Cable Packaging Machine

Automatic Cable Coil Strapping and Shrink Wrapping Machine

Automatic Cable Coiling and Wrapping Machine

Automatic Cable Coiling Machine with Microcomputer Control

Automatic Cable Spooling and Coiling Machine

Automatic Double Coiler

Cartesian Coordinate Palletizer

Circinate Film Cable Coil Automatic Packaging Machine

Film Heat Shrinking Machine

Robotic Palletizer

Auxiliary Equipment

Solution

News

Blog

Contact Us