Top 10 Automated Packaging Machines Revolutionizing Productivity in 2023

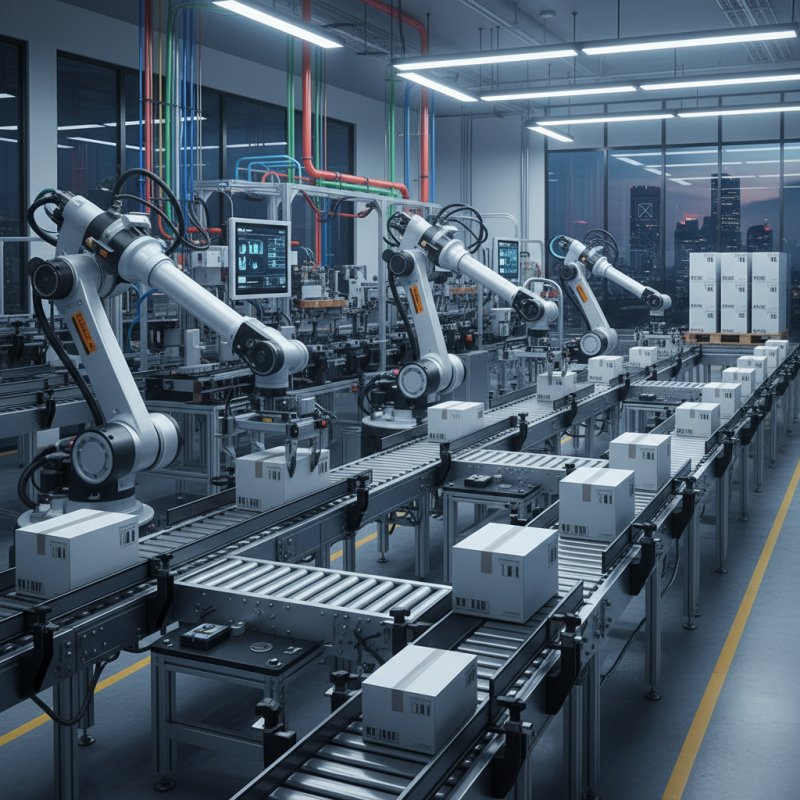

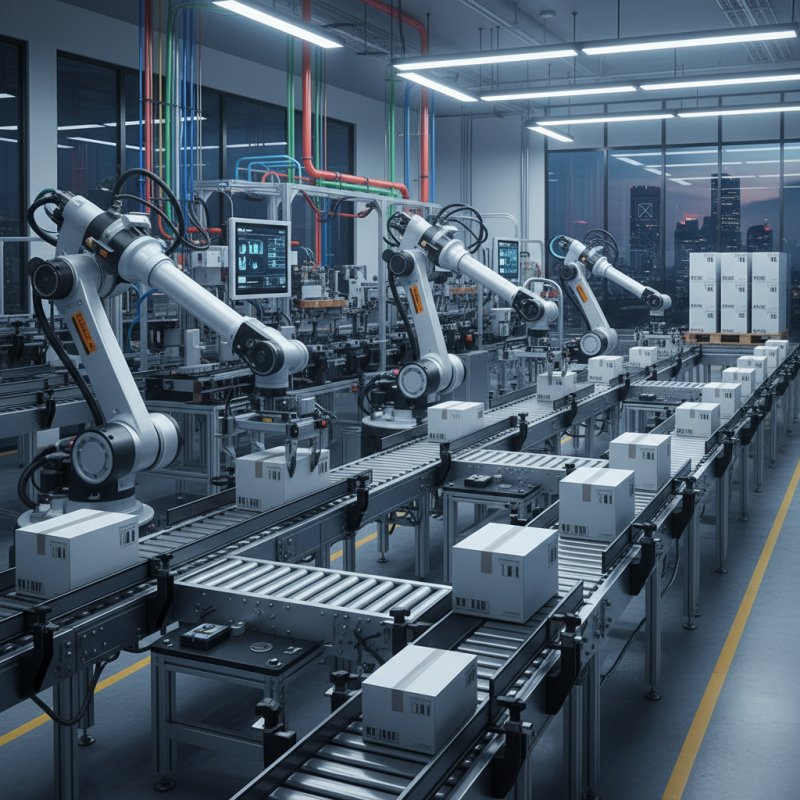

In the fast-evolving landscape of manufacturing and logistics, the demand for efficiency and productivity has never been greater. One of the most transformative innovations in this arena is the Automated Packaging Machine. These machines streamline packaging processes, reduce labor costs, and enhance overall operational efficiency. By integrating advanced technology, they offer solutions that cater to a variety of production needs, from small-scale operations to large manufacturing plants.

As we delve into the Top 10 Automated Packaging Machines revolutionizing productivity in 2023, we will explore how these cutting-edge machines are not only optimizing workflows but also setting new standards for speed and accuracy. Through automation, businesses can respond to market demands more swiftly, minimize waste, and ensure consistent packaging quality. The inherent adaptability of automated systems allows companies to pivot quickly to meet changing consumer preferences while maintaining profitability.

In this article, we will highlight the key features and benefits of these packaging machines, illustrating their significant impact on various industries. The integration of automated packaging solutions is reshaping the way products are packaged and distributed, making it a crucial trend to watch as we move further into the year.

Top Automated Packaging Machines Enhancing Efficiency in 2023

In 2023, automated packaging machines are at the forefront of enhancing operational efficiency across various industries. These innovative technologies streamline packaging processes, significantly reducing manual labor while improving accuracy and speed. By integrating advanced sensors and software, these machines provide real-time data analytics, enabling businesses to optimize their workflows. Automated packaging systems eliminate bottlenecks, ensuring a continuous flow that meets the demands of a fast-paced market.

The rise of smart automation has transformed traditional packaging lines into highly efficient operations. Machines equipped with artificial intelligence are capable of adapting to different product sizes and types, which minimizes downtime and maximizes throughput. The flexibility of modern automated packaging solutions allows companies to respond quickly to changing consumer preferences, reducing lead times and increasing customer satisfaction. As industries strive to achieve sustainable practices, these machines also help reduce material waste, contributing to a more eco-friendly approach in packaging processes. Through the integration of cutting-edge technology, automated packaging machines are enhancing efficiency and setting new standards for productivity in 2023.

Top 10 Automated Packaging Machines Revolutionizing Productivity in 2023

| Machine Type |

Speed (units/hour) |

Automation Level (%) |

Primary Function |

Key Feature |

| Horizontal Flow Wrapper |

120 |

95 |

Packaging Snacks |

Compact Design |

| Automatic Labeling Machine |

300 |

90 |

Product Labeling |

Multi-Format Capability |

| Cartoning Machine |

150 |

88 |

Boxing Products |

Automated Folding |

| Robot Case Packer |

100 |

92 |

Packing Cases |

Flexibility in Packing |

| Shrink Wrapper |

200 |

89 |

Shrink Packaging |

Energy Efficient |

| Stretch Wrapper |

80 |

85 |

Pallet Wrapping |

User-Friendly Controls |

| Fill & Seal Machine |

250 |

93 |

Liquid & Semi-Liquid |

High Precision Filling |

| Bagger Machine |

180 |

87 |

Bulk Items Packaging |

Automatic Quantity Control |

| Vacuum Packaging Machine |

150 |

91 |

Extending Shelf Life |

Controlled Atmosphere |

| Pouch Fill & Seal Machine |

220 |

94 |

Snack Foods |

Versatile Pouch Sizes |

Key Features Driving Productivity in Modern Packaging Solutions

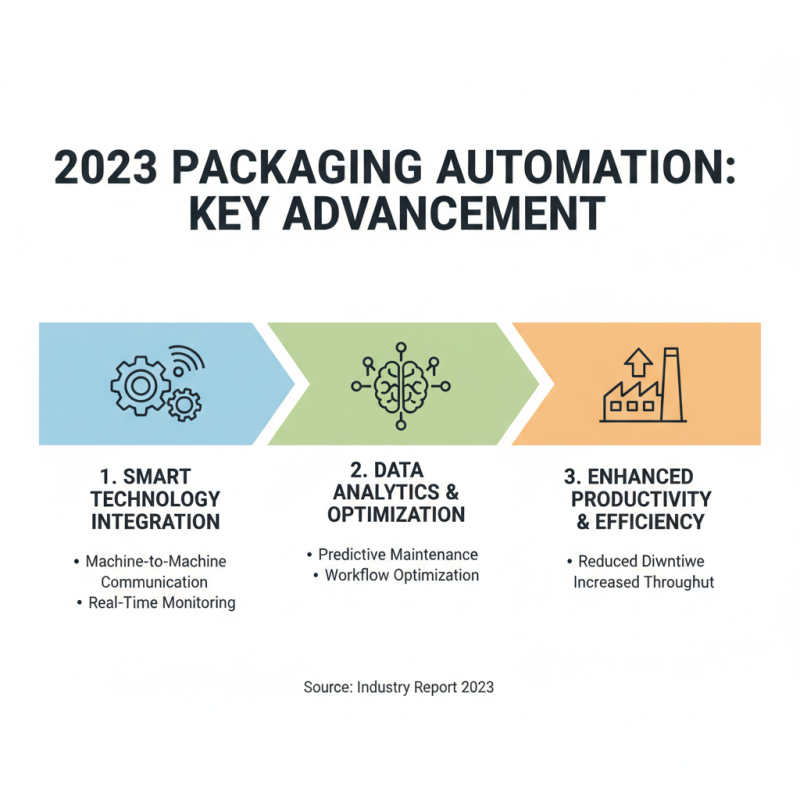

In 2023, the landscape of packaging automation has undergone significant transformation, driven by key features that enhance productivity and efficiency. One of the foremost advancements is the integration of smart technology, which allows packaging machines to communicate with other systems within the production line. This connectivity ensures real-time monitoring and data analytics, enabling manufacturers to quickly address any disruptions and optimize workflows for maximum output.

Additionally, flexibility has emerged as a critical feature in modern packaging solutions. Automated machines now utilize modular designs that allow for quick adjustments to accommodate various packaging sizes and types. This adaptability not only reduces downtime during product changeovers but also enables companies to keep pace with fluctuating consumer demands. Furthermore, energy-efficient technologies are gaining prominence, as they help reduce operational costs and minimize environmental impact, aligning with the growing emphasis on sustainability in the industry. These key features collectively empower businesses to enhance their productivity and maintain a competitive edge in the evolving market.

Market Trends: Growth Statistics for Automated Packaging Technologies

The automated packaging industry has experienced remarkable growth in 2023, driven by advancements in technology and shifting consumer demands. This surge can be attributed to the increasing need for efficiency in production lines, where manufacturers are seeking to minimize human intervention and reduce labor costs. Statistics indicate that the global market for automated packaging machines is expected to expand significantly, with projections suggesting a compound annual growth rate (CAGR) in the double digits over the next several years.

Simultaneously, the rise of e-commerce and the corresponding demand for quick and reliable packaging solutions has further fueled this trend. Companies are investing in sophisticated systems that not only speed up the packaging process but also improve accuracy and reduce waste. As sustainability becomes a priority, many of these automated machines are designed to utilize eco-friendly materials and minimize excess packaging, aligning with the growing consumer preference for environmentally responsible practices. The integration of artificial intelligence and robotics into automated packaging solutions is also playing a pivotal role, enabling businesses to adapt to fluctuating market demands with greater agility and precision.

Top 10 Automated Packaging Machines Revolutionizing Productivity in 2023

Comparative Analysis: Costs and ROI of Automated Packaging Machines

The adoption of automated packaging machines is transforming productivity across various industries, and understanding their costs and return on investment (ROI) is crucial for businesses. According to a report by Research and Markets, the global automated packaging market is projected to grow at a CAGR of 12.5% from 2021 to 2026, indicating widespread recognition of the benefits of automation. The initial investment for automated packaging systems can range from $40,000 to over $300,000 depending on complexity and functionality. However, companies are increasingly finding that these upfront costs are offset by significant savings in labor and increased efficiency.

In terms of ROI, a study by the Packaging Machinery Manufacturers Institute (PMMI) revealed that businesses implementing automated packaging solutions can see ROI within 1-3 years. These systems not only reduce labor costs by up to 50% but also enhance production speed and accuracy, minimizing errors and waste. For instance, automated packaging lines can operate at speeds of up to 300 packages per minute, significantly outpacing manual processes. Furthermore, improved consistency leads to better product quality and customer satisfaction, establishing a compelling case for automation as a strategic investment in enhancing business competitiveness.

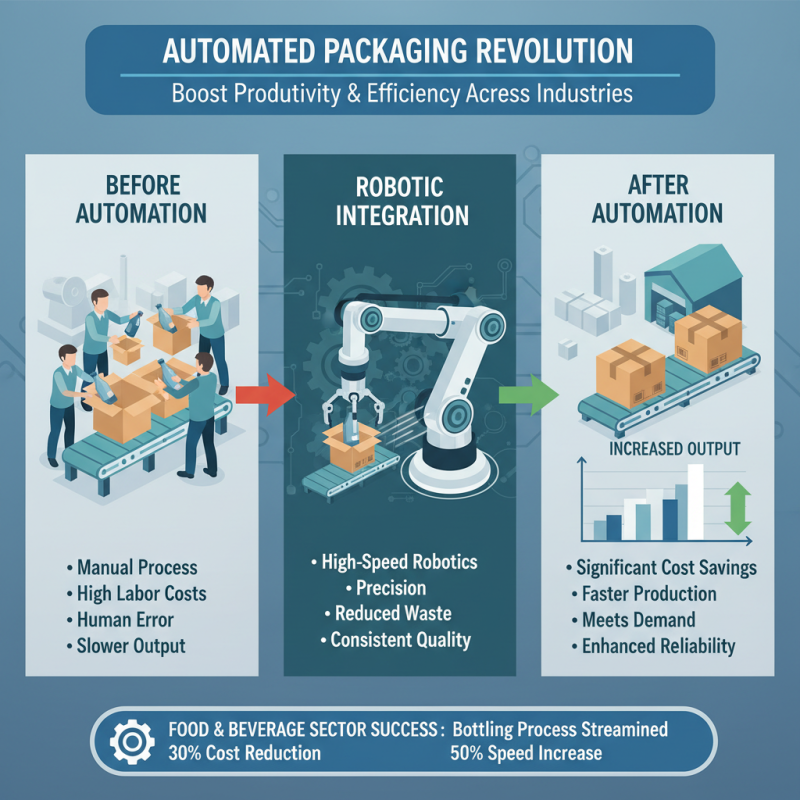

Case Studies: Successful Implementation of Automation in Different Industries

In recent years, various industries have successfully integrated automated packaging machines to enhance their productivity and efficiency. For instance, in the food and beverage sector, a company implemented a high-speed robotic packaging system that streamlined its bottling process. This automation not only increased the speed of production but also minimized human error, ensuring that products were consistently packaged to specifications. The result was a notable reduction in labor costs and an increase in output, allowing the company to meet growing consumer demands more effectively.

Similarly, in the cosmetics industry, a leading manufacturer adopted an automated cartoning machine that efficiently packages products into boxes with precision. By utilizing advanced sensors and robotics, the machine can adjust to different product sizes and shapes without significant downtime. This flexibility enabled the manufacturer to respond quickly to market trends and seasonal changes, thus maximizing their market competitiveness. The successful implementation of this automation not only improved throughput but also enhanced packaging integrity, leading to higher customer satisfaction rates.

Home

About Us

Products

Stranding & Bunching Machine

Extrusion Lines

Cable Packaging Machine

Automatic Cable Coil Strapping and Shrink Wrapping Machine

Automatic Cable Coiling and Wrapping Machine

Automatic Cable Coiling Machine with Microcomputer Control

Automatic Cable Spooling and Coiling Machine

Automatic Double Coiler

Cartesian Coordinate Palletizer

Circinate Film Cable Coil Automatic Packaging Machine

Film Heat Shrinking Machine

Robotic Palletizer

Auxiliary Equipment

Solution

News

Blog

Contact Us