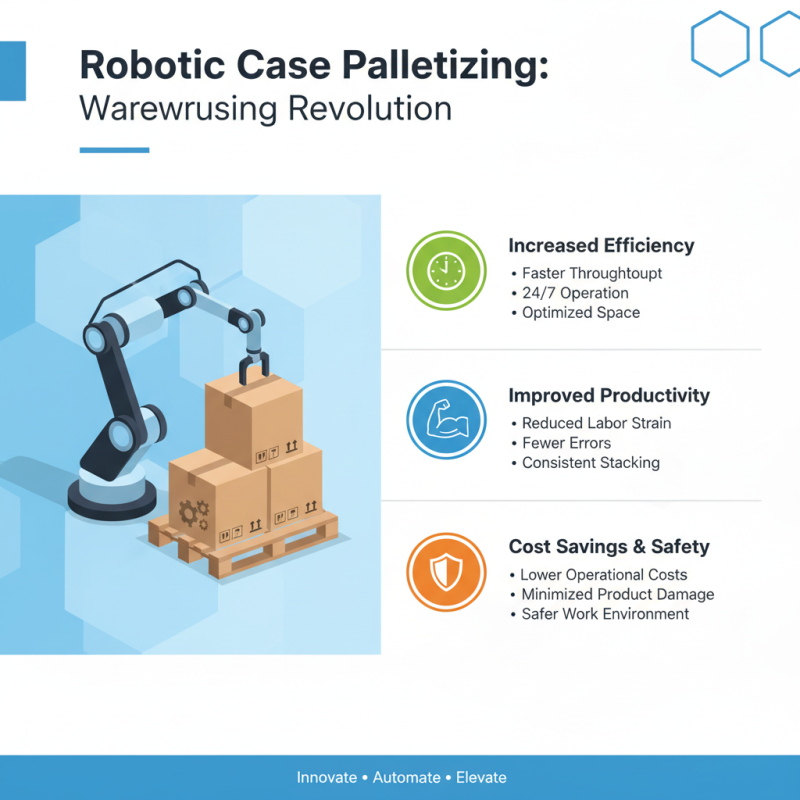

Top Benefits of Robotic Case Palletizing for Modern Warehousing Operations

In the rapidly evolving landscape of modern warehousing operations, the implementation of advanced technologies plays a crucial role in enhancing efficiency and productivity. One of the standout innovations in this sector is Robotic Case Palletizing, a sophisticated solution designed to automate the packing and stacking of products onto pallets. According to Dr. Emily Johnson, an expert in automation systems, "Robotic Case Palletizing not only streamlines the packing process but also significantly reduces human error, leading to a more reliable operation."

The benefits of Robotic Case Palletizing extend beyond mere efficiency; they encompass improved safety, consistent product handling, and the ability to adapt to various products and packaging types. As warehouses face challenges such as labor shortages and the need for faster turnaround times, this technology offers a viable solution to meet increasing demands. Moreover, the integration of robotics in palletizing processes allows companies to optimize their workflow, allowing employees to focus on more complex tasks, thereby enhancing overall productivity.

In this context, as we explore the top benefits of Robotic Case Palletizing for modern warehousing operations, it becomes clear that embracing such technological advancements is not just a trend but a strategic necessity in maintaining a competitive edge. The integration of robotics promises not only immediate operational gains but also long-term sustainability and growth for businesses in the logistics sector.

Overview of Robotic Case Palletizing in Warehousing

Robotic case palletizing has emerged as a transformative solution within modern warehousing operations, significantly enhancing efficiency and productivity. By automating the palletizing process, businesses can streamline the handling of goods, reducing the physical strain on workers and minimizing the risk of errors associated with manual labor. The integration of robotics allows warehouses to operate at a faster pace, as machines can consistently and accurately stack products, optimizing space and ensuring stability for transportation.

The implementation of robotic case palletizers also provides flexibility and adaptability to changing demands. With advanced programming and modular designs, these robotic systems can be easily reconfigured to handle a variety of products and pallet patterns without extensive downtime. This not only accommodates seasonal fluctuations in demand but also supports diverse product lines, making it an ideal choice for warehouses aiming to stay competitive in a fast-paced market. Furthermore, real-time data tracking can be integrated into these systems, enabling better inventory management and reducing waste, which enhances overall operational efficiency.

Key Advantages of Integrating Robotics in Palletizing Operations

The integration of robotics in palletizing operations presents a transformative shift for modern warehousing. One key advantage is the significant increase in efficiency. Robotic systems can operate continuously and handle high throughput, which minimizes downtime associated with manual labor. This enhanced efficiency leads to quicker order fulfillment and improved overall productivity in warehousing environments. Additionally, robots can be programmed for precision tasks, ensuring consistency in pallet formation and reducing the risk of errors that could arise from manual operations.

Another critical benefit of robotic palletizing is the enhancement of workplace safety. By delegating the heavy and repetitive lifting tasks to robots, the risk of workplace injuries decreases significantly. Employees can focus on more strategic roles that require human oversight, thereby fostering a safer and more ergonomic work environment. Robotics also helps warehouses meet fluctuating demands without overburdening their workforce, as robots can be adjusted and reprogrammed to handle varying sizes and weights of products with ease. This adaptability not only streamlines operations but also aids in managing labor costs in a highly competitive market.

Impact on Operational Efficiency and Cost Reduction

Robotic case palletizing has emerged as a transformative solution for modern warehousing operations, significantly impacting operational efficiency and cost reduction. According to a report by MarketsandMarkets, the global palletizing equipment market is projected to grow from $3.76 billion in 2020 to $5.18 billion by 2025, reflecting the increasing adoption of robotic systems in logistics. One of the primary benefits of robotic case palletizing is the ability to enhance throughput and minimize human error. Automated systems can operate continuously, achieving speeds that can surpass manual labor while maintaining precise stacking patterns. This capability not only leads to faster loading and unloading times but also optimizes storage space, resulting in a more efficient use of warehouse resources.

Moreover, robotic case palletizing contributes to significant cost savings. According to research from the Association for Advancing Automation (A3), businesses that implement robotic systems can reduce labor costs by up to 30%. Additionally, the reduction in product damage due to consistent handling practices further lowers operational expenses related to returns and reprocessing. The integration of robotics enables warehouses to operate with fewer personnel, reallocating valuable human resources to more strategic tasks, ultimately driving higher productivity across operations.

As the demand for faster, more efficient warehouse solutions grows, organizations investing in robotic palletizing are likely to see a substantial return on investment, making it a critical component of modern supply chain management.

Enhancements in Safety and Ergonomics for Warehouse Staff

The integration of robotic case palletizing systems in modern warehousing operations has significantly enhanced the safety and ergonomic conditions for warehouse staff. Traditional palletizing methods often require workers to engage in repetitive lifting and handling of heavy loads, leading to musculoskeletal injuries and increased physical strain over time. By employing robotic systems, warehouses can minimize the need for manual labor in these physically demanding tasks, allowing workers to focus on higher-value activities that require cognitive skills rather than strenuous physical effort.

Moreover, automation through robotic palletizing not only reduces the risk of injury but also fosters a safer working environment. Robots can operate in a controlled manner, ensuring that products are handled without the risk of dropping or mishandling them—a common hazard in traditional methods. This decreased risk of accidents contributes to overall workplace safety, leading to fewer injuries, lower workers' compensation costs, and improved morale among staff. With easier access to technology that mitigates physical strain, warehouses are evolving into safer spaces where employees can work efficiently without compromising their health.

Future Trends in Robotic Palletizing Technology and Applications

The landscape of robotic palletizing technology is rapidly evolving, driven by advancements in artificial intelligence and machine learning. According to a recent report by ResearchAndMarkets, the global robotic palletizing market is expected to grow at a CAGR of 9.2% from 2021 to 2028, underlining the increasing adoption of automation in warehousing operations. This growth is largely attributed to enhanced efficiency, reduced labor costs, and improved safety standards. Robots are becoming more intelligent, capable of handling a wider variety of products and integrating seamlessly with existing warehouse management systems.

Future trends indicate a significant move towards collaborative robots, or cobots, which can work side-by-side with human workers. These systems are designed to be easily programmable and can adapt to different tasks, allowing for greater flexibility in warehouse operations. A report by the International Federation of Robotics highlighted that by 2025, over 40% of all industrial robots will be collaborative in nature. Furthermore, the integration of IoT technology will enable real-time data sharing and analytics, enhancing operational visibility and decision-making. As companies continue to invest in these innovative technologies, the potential for increased productivity and operational efficiency will be transformative for modern warehousing.

Top Benefits of Robotic Case Palletizing for Modern Warehousing Operations

| Benefit |

Description |

Impact on Operations |

| Increased Efficiency |

Robotic palletizers operate continuously without fatigue, allowing for higher throughput. |

Boosts productivity by up to 30% compared to manual processes. |

| Cost Savings |

Reduces labor costs over time and minimizes product damage through precision handling. |

Potential reduction in operational costs by 15-25%. |

| Space Optimization |

Compact design can maximize vertical storage space. |

Improves warehouse layout efficiency and storage capacity. |

| Flexibility and Scalability |

Easily programmable for different pallet patterns and product types. |

Supports changing business needs and growth. |

| Safety Improvement |

Reduces the risk of workplace injuries associated with manual handling. |

Enhances overall workplace safety and employee well-being. |

Home

About Us

Products

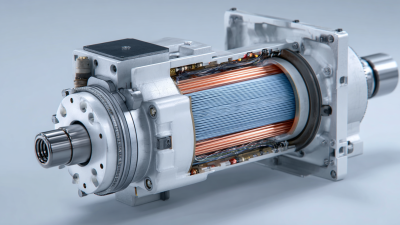

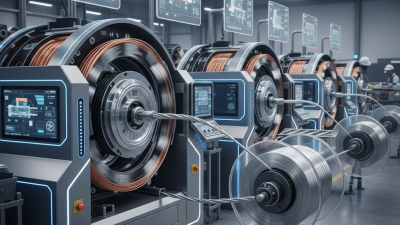

Stranding & Bunching Machine

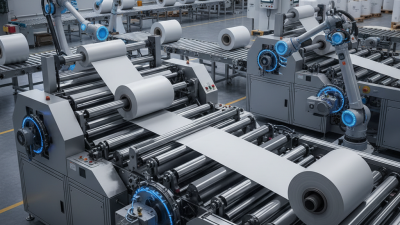

Extrusion Lines

Cable Packaging Machine

Automatic Cable Coil Strapping and Shrink Wrapping Machine

Automatic Cable Coiling and Wrapping Machine

Automatic Cable Coiling Machine with Microcomputer Control

Automatic Cable Spooling and Coiling Machine

Automatic Double Coiler

Cartesian Coordinate Palletizer

Circinate Film Cable Coil Automatic Packaging Machine

Film Heat Shrinking Machine

Robotic Palletizer

Auxiliary Equipment

Solution

News

Blog

Contact Us