The Best Automated Shrink Wrap Machines for Efficient Packaging Solutions?

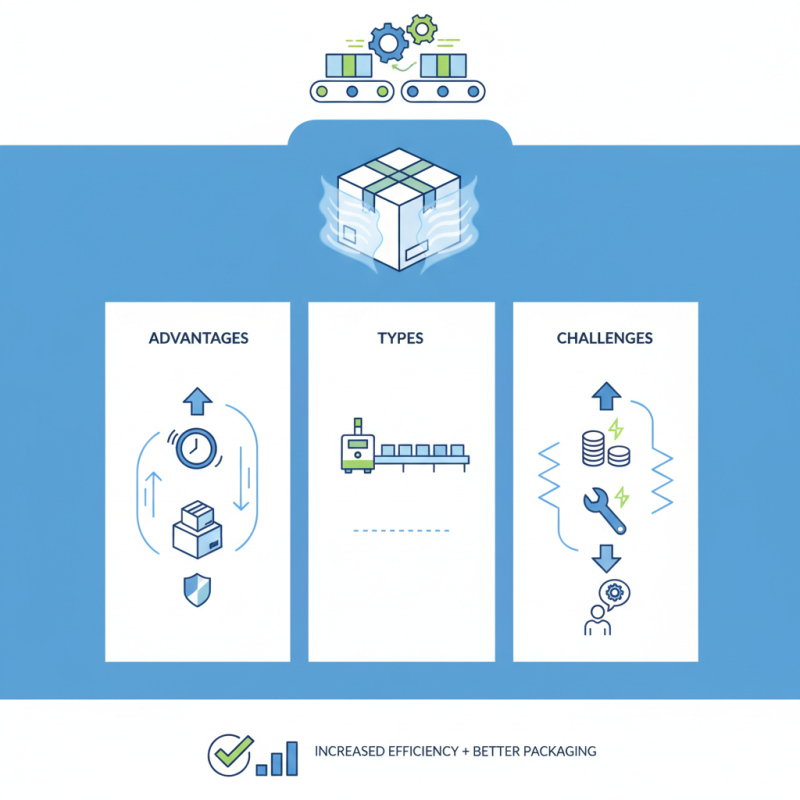

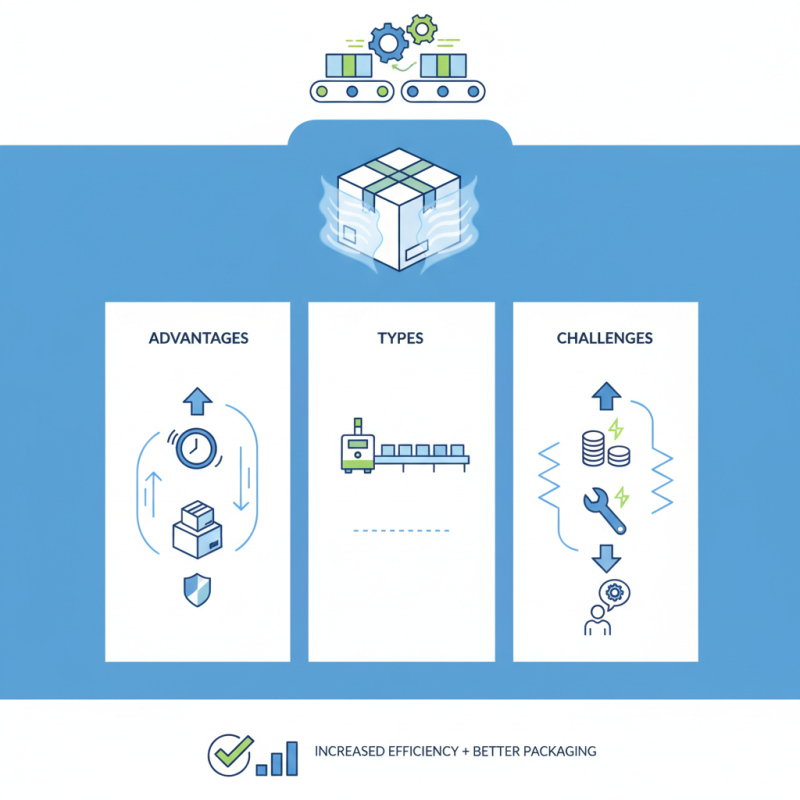

In today's fast-paced packaging industry, efficiency is paramount. Automated Shrink Wrap Machines play a crucial role in streamlining the packaging process. These machines offer businesses a solid solution for protecting products while enhancing productivity. They simplify tasks that would otherwise require manual labor.

Various models cater to different needs. Some machines are compact, ideal for small operations. Others are large-scale, designed for high-volume packaging. This diversity means that businesses can find a machine that fits their specific requirements. It's essential to evaluate the features and capabilities of each type.

While these machines bring significant advantages, challenges can arise too. Initial costs may be high, and technical issues could occur. Moreover, training staff to operate the machines effectively is necessary. Companies must weigh these considerations against the benefits. In the end, investing in the right Automated Shrink Wrap Machines can lead to increased efficiency and better packaging solutions.

Factors to Consider When Choosing Automated Shrink Wrap Machines

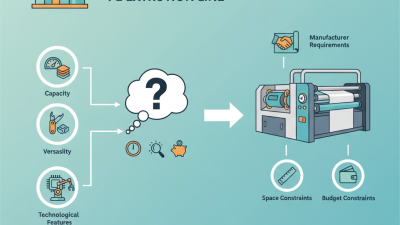

Choosing the right automated shrink wrap machine involves several important factors. Speed and efficiency are crucial for optimizing your packaging line. Look for machines that can handle high volumes without sacrificing quality. Consider if the machine offers adjustable settings for different package sizes. Flexibility in size can save time on changeovers.

Material compatibility should also be evaluated. Not all machines work with all types of films. Ensure that your chosen machine can efficiently use the specific shrink films you plan to work with. This can impact the final appearance and protection of your products.

Lastly, think about the machine’s maintenance needs. Machines with complex mechanisms may require more upkeep. Simplicity can be beneficial for a smoother operation. Examine if you have the right technical support for any repairs. Balancing these considerations can lead to better overall productivity. It's essential to reflect on your unique needs before committing to a machine.

Types of Automated Shrink Wrap Machines Available on the Market

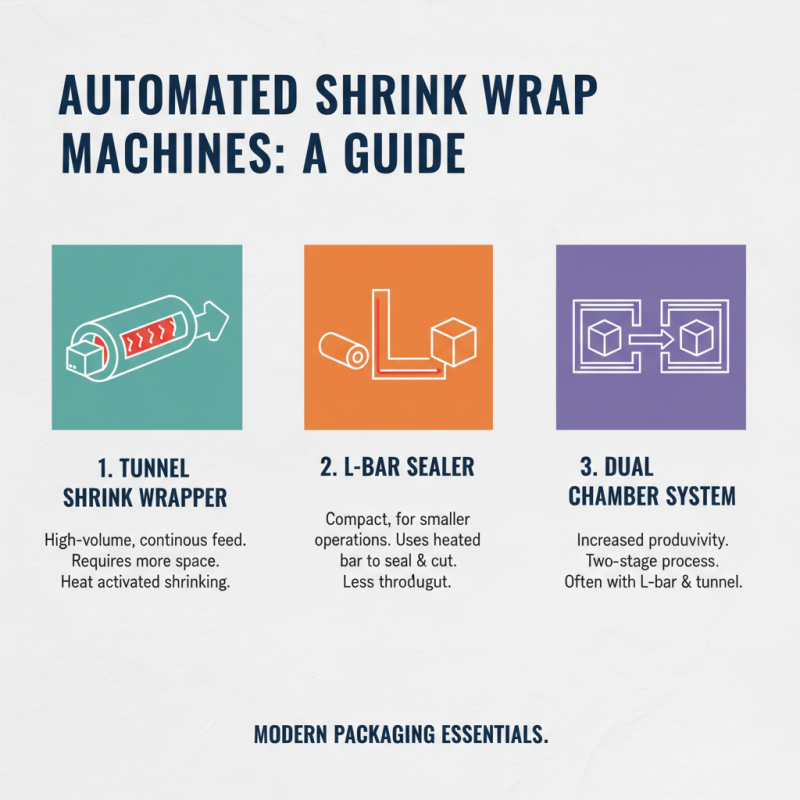

Automated shrink wrap machines are crucial for modern packaging. They come in various types, each serving unique needs. The most common types include tunnel shrink wrap machines, L-bar sealers, and dual chamber systems. Tunnel machines shrink wrap products after they pass through a heated tunnel. It’s efficient but can require more space. L-bar sealers, on the other hand, are compact and ideal for smaller operations. They use a heated bar to create seals but may struggle with high volume demands.

In the 2022 Packaging Automation Market Analysis report, the automated shrink wrap segment grew by 15% from the previous year. This growth reflects rising demand across various industries. However, many companies face a significant learning curve when adopting new equipment. Proper training is essential to avoid costly mistakes. Some users report difficulties in achieving consistent sealing. Maintaining the machine is also critical. A lack of regular upkeep can lead to breakdowns and inefficiency.

Despite their advantages, automated shrink wrap machines can be expensive. Smaller businesses may find initial costs daunting. However, investing in automation often pays off over time. Increased productivity can lead to higher profits. The right machine can streamline operations, but choosing the wrong one can cause setbacks. Overall, understanding the different types is vital for making informed decisions in the evolving packaging landscape.

Key Features of High-Quality Shrink Wrap Machines

When selecting a shrink wrap machine, there are key features to consider. Speed is one of them. An efficient machine should handle a high volume of packages without sacrificing quality. Look for machines capable of wrapping multiple packages in a minute. This feature is vital for businesses with tight deadlines.

Next, versatility is essential. A high-quality shrink wrap machine should work with various products. It should easily accommodate items of different shapes and sizes. This flexibility can be a game-changer for diverse packaging needs. Additionally, ease of use is also important. The machine should have intuitive controls, reducing the learning curve for operators.

Lastly, durability matters. Machines should withstand regular use without frequent breakdowns. Regular maintenance can be seen as a chore, but it’s necessary for longevity. Some machines may require specific skills to operate and maintain effectively. A comprehensive user manual can mitigate these challenges, making it easier for staff to troubleshoot common issues. Finding the right balance between features and usability can lead to better packaging solutions.

The Best Automated Shrink Wrap Machines for Efficient Packaging Solutions

This chart illustrates the key features of high-quality automated shrink wrap machines, highlighting their speed, film width, temperature range, voltage, and weight. These features are essential for efficient packaging solutions.

Benefits of Using Automated Shrink Wrap for Packaging

Automated shrink wrap machines streamline the packaging process. They enhance efficiency while reducing labor costs. Businesses can accommodate higher volumes quickly. This technology minimizes packaging errors, ensuring products are securely wrapped every time. It creates a consistent look and feel, promoting brand image.

The benefits of using automated shrink wrap are significant. This method protects products from dust, moisture, and damage during transport. It can extend shelf life for perishable items. Automated systems provide flexibility, allowing for various product sizes and shapes. However, initial setup can be challenging. Companies must invest time in training staff and fine-tuning the machine’s settings.

Environmentally, shrink wrap offers both pros and cons. While it reduces waste by efficiently wrapping multiple items, the material is often non-biodegradable. This challenge prompts businesses to seek sustainable practices. It’s essential to balance efficiency with ecological responsibility. Reassessing packaging choices regularly can lead to better solutions.

Maintenance Tips for Ensuring Optimal Machine Performance

Maintaining automated shrink wrap machines is vital for optimal performance. Regular checks can extend the life of your equipment. According to a recent industry report, over 30% of shrink wrap machine failures are due to improper maintenance. This statistic highlights the importance of a consistent maintenance routine.

One critical aspect of maintenance is the machine’s sealing element. This part should be cleaned regularly. Buildup can cause seals to fail, leading to product damage. Lubricating moving parts every few months can also prevent unnecessary wear and tear. Failure to do so often results in costly repairs.

Monitoring your machine’s speed settings is essential too. An overly fast or slow operation can affect packaging quality. A report from Packaging World indicates that correct speed can increase efficiency by 25%. Regularly review and adjust settings based on production needs. It's easy to overlook these details, but doing so can greatly enhance machine reliability.

The Best Automated Shrink Wrap Machines for Efficient Packaging Solutions

| Model |

Speed (packages/min) |

Film Width (inches) |

Power (Watts) |

Weight (lbs) |

Price ($) |

| Model A |

25 |

20 |

1500 |

100 |

1500 |

| Model B |

30 |

18 |

1600 |

95 |

1700 |

| Model C |

20 |

16 |

1400 |

85 |

1200 |

| Model D |

35 |

24 |

1800 |

110 |

1900 |

Home

About Us

Products

Stranding & Bunching Machine

Extrusion Lines

Cable Packaging Machine

Automatic Cable Coil Strapping and Shrink Wrapping Machine

Automatic Cable Coiling and Wrapping Machine

Automatic Cable Coiling Machine with Microcomputer Control

Automatic Cable Spooling and Coiling Machine

Automatic Double Coiler

Cartesian Coordinate Palletizer

Circinate Film Cable Coil Automatic Packaging Machine

Film Heat Shrinking Machine

Robotic Palletizer

Auxiliary Equipment

Solution

News

Blog

Contact Us