Why Choose a Double Twist Bunching Machine for Your Production Needs?

In the world of manufacturing, efficiency and precision are vital. One machine that stands out is the Double Twist Bunching Machine. This equipment streamlines the production process, enhancing productivity significantly. Many industries rely on it for consistent results.

Investing in a Double Twist Bunching Machine can seem daunting. However, the benefits may outweigh initial concerns. This machine offers flexibility and adaptability. Customization options allow for various products. It can produce items with different specifications seamlessly. Yet, it is essential to evaluate your specific needs carefully. Not every production line may benefit fully from this machine.

Challenges may arise in the initial setup phase. Proper training is crucial for maximizing efficiency. The learning curve can be steep for some operators. Reflection on these aspects is important. But when managed effectively, the Double Twist Bunching Machine can transform your production line and elevate your output.

Benefits of Using a Double Twist Bunching Machine in Production

A double twist bunching machine offers numerous benefits for production processes. It efficiently twists and bunches materials into desired shapes and sizes. This machine excels in creating consistent products, essential for quality control. The precision ensures that each batch meets specified standards. Businesses see significant boosts in productivity and lower labor costs.

Tips: Regularly maintain the machine to avoid breakdowns. Schedule upkeep every few months to keep it running smoothly. A well-maintained machine can enhance efficiency dramatically.

Another advantage is versatility. Different materials can be processed easily, expanding production capabilities. Companies can adapt to market demands quickly. This flexibility is crucial in today’s fast-paced environment. However, adjusting settings can sometimes be tricky. Operators need to be trained carefully.

Tips: Invest time in training staff. Understanding all aspects of machine operation minimizes mistakes. A knowledgeable team can leverage the machine's full potential, driving improvements.

In conclusion, a double twist bunching machine can greatly enhance production. Its design and functionality can lead to more efficient manufacturing processes. Yet, challenges like maintenance and operation should not be ignored.

Why Choose a Double Twist Bunching Machine for Your Production Needs? - Benefits of Using a Double Twist Bunching Machine in Production

| Benefit |

Description |

Impact on Production |

| Increased Efficiency |

Machinery allows for rapid bunching, reducing production time. |

Higher output rates, leading to greater profitability. |

| Consistent Quality |

Ensures uniform bunch size and tension, enhancing product standardization. |

Improves customer satisfaction and reduces waste. |

| Versatility |

Can work with various material types and sizes. |

Flexible production options catering to diverse market needs. |

| Reduced Labor Costs |

Automation reduces the need for manual labor in bunching tasks. |

Lower operational costs, allowing for better resource allocation. |

| Enhanced Safety |

Minimizes manual handling, reducing the risk of workplace injuries. |

Creates a safer working environment, ensuring staff well-being. |

How a Double Twist Bunching Machine Boosts Efficiency and Output

A double twist bunching machine significantly enhances production efficiency. It achieves this by streamlining the twisting and bundling process of products like wires and cables. According to a recent industry report, companies using these machines can see output increases of up to 40%. This means faster turnaround times and improved response to market demands.

However, it's essential to properly maintain the machine. Regular checks on components, such as gearboxes and motors, can prevent downtime. A well-maintained machine runs smoother and reduces the risk of defects. Implementing a routine maintenance schedule can increase longevity and performance.

Tip: Always train staff on best practices for operation. Properly trained personnel can identify issues early, avoiding costly repairs. Don't overlook the importance of safety protocols. A safe workspace is crucial for maintaining productivity levels in any production environment.

Key Features to Look for in a Double Twist Bunching Machine

When selecting a double twist bunching machine, there are several key features to consider. First, look for machines that offer flexible adjustments. This is crucial for producing various yarn types and sizes. The ability to easily change settings makes production more efficient. Speed control also plays a vital role. Machines that allow operators to manage speed can enhance quality by preventing tension issues.

Another important feature is the machine's durability. A robust frame reduces maintenance costs over time. Reliable parts minimize breakdowns during operations. It’s essential to occasionally review the condition of these machines. Small issues can lead to bigger problems if not addressed promptly.

Additionally, user-friendly controls can significantly improve productivity. Operators should be able to easily navigate settings without extensive training. A complex interface may slow down production and frustrate workers. Regular evaluations of the machine's performance can help identify areas for improvement. It’s not just about initial output; ongoing efficiency is key in this industry.

Double Twist Bunching Machine Features Comparison

Comparison of Double Twist Bunching Machines with Other Bunching Equipment

When comparing double twist bunching machines to other bunching equipment, a few critical factors come into play. Double twist bunching machines provide greater efficiency in the production line. They can produce up to 25% more output than traditional bunching machines, according to a recent industry report. This increased productivity can significantly enhance a company’s bottom line.

Another advantage is the flexibility in handling various materials. Double twist bunching machines can manage different yarn types, from fine to thick fibers. This versatility is lacking in many single bunching systems. However, it's essential to note that not all double twist machines offer the same performance. Operators may face challenges, like the machine's maintenance needs, leading to potential downtime.

Moreover, double twist machines' energy consumption is often higher, increasing operational costs. Some manufacturers reported energy usage rising by 15% compared to single twist alternatives. This factor can impact the decision-making process when assessing long-term investments. Understanding these nuances is crucial for businesses aiming to optimize production efficiency. Balancing efficiency, cost, and maintenance is a complex but necessary task.

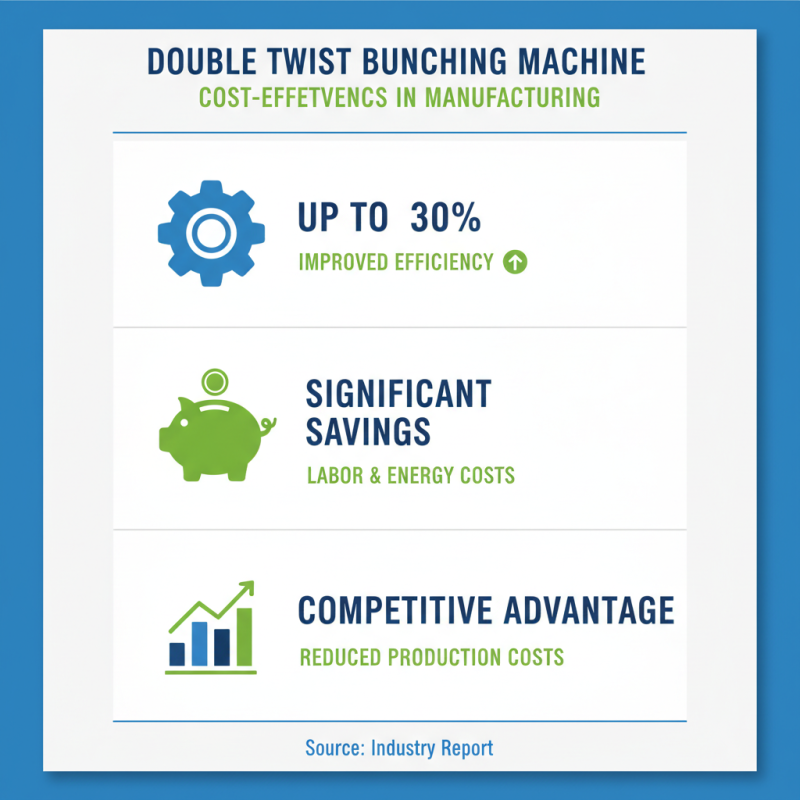

Cost-Effectiveness of Investing in a Double Twist Bunching Machine

The cost-effectiveness of investing in a double twist bunching machine cannot be overstated. In the competitive manufacturing landscape, companies are constantly seeking ways to reduce production costs. According to a recent industry report, integrating a double twist bunching machine can improve efficiency by up to 30%. This translates to significant savings on labor and energy costs over time.

Additionally, these machines are known for their versatility. They can handle various materials, which reduces downtime and maintenance expenses. A study highlighted that businesses employing double twist bunching technology reported a 15% increase in overall output within the first year. This means faster delivery times and happier customers. However, this higher output does come with considerations regarding the initial investment.

Investing in such equipment requires careful financial planning. While the upfront costs might seem challenging, the long-term benefits are substantial. Manufacturers must evaluate their production needs and their capacity for equipment upkeep. If not managed appropriately, the returns might falter. Ultimately, investing in a double twist bunching machine involves balancing potential gains against financial commitments.

Home

About Us

Products

Stranding & Bunching Machine

Extrusion Lines

Cable Packaging Machine

Automatic Cable Coil Strapping and Shrink Wrapping Machine

Automatic Cable Coiling and Wrapping Machine

Automatic Cable Coiling Machine with Microcomputer Control

Automatic Cable Spooling and Coiling Machine

Automatic Double Coiler

Cartesian Coordinate Palletizer

Circinate Film Cable Coil Automatic Packaging Machine

Film Heat Shrinking Machine

Robotic Palletizer

Auxiliary Equipment

Solution

News

Blog

Contact Us