How to Choose the Right Robotic Palletisers for Your Warehouse Needs

In today's fast-paced industrial landscape, the efficiency and agility of warehouse operations are paramount. One key player in enhancing these operations is the use of Robotic Palletisers. As businesses seek to optimize their logistics and reduce labor costs, the integration of robotic systems into palletizing processes has become increasingly popular. Industry expert Dr. Emily Carter, a leading figure in automation technology, asserts, "Choosing the right Robotic Palletisers can transform your warehousing capabilities and ensure seamless supply chain management."

Selecting the most suitable Robotic Palletisers involves understanding various factors including the type of products being handled, the layout of the warehouse, and the expected throughput. With advancements in technology, today's robotic palletizers come equipped with smart features such as vision systems and adaptable gripping mechanisms, which allow them to manage a wide range of products efficiently. As companies face the challenge of meeting increasing consumer demands, investing in the right robotic solutions becomes critical to maintaining competitiveness and operational efficiency.

Understanding the Basics of Robotic Palletisers in Warehousing

In modern warehousing, robotic palletisers have emerged as a pivotal technology, streamlining the process of palletizing goods efficiently. These systems are designed to automate the stacking of products onto pallets, thus reducing labor costs and increasing throughput. By understanding the fundamental principles behind robotic palletisers, warehouse managers can make informed decisions about adopting this technology to enhance their operational capabilities.

The basic operation of a robotic palletiser involves a robotic arm equipped with various end-of-arm tooling (EOAT) designed for specific products. These robots can handle an array of items, from boxes to bags, and adapt to the varying sizes and shapes of products typically found in a warehouse. The integration of sophisticated vision systems allows these machines to identify and locate products with precision, ensuring that they are stacked safely and securely. Moreover, the flexibility of robotic palletisers means they can easily be reprogrammed or reconfigured to accommodate changes in production lines or cargo types, making them a valuable asset for warehouses that require adaptability in their logistics processes.

How to Choose the Right Robotic Palletisers for Your Warehouse Needs

| Dimension |

Description |

Considerations |

Typical Use Cases |

| Payload Capacity |

Weight that the palletiser can handle. |

Match the payload to your product weight. |

Food and beverage, consumer goods. |

| Speed |

Rate at which the palletiser can operate. |

Consider throughput requirements. |

High-volume distribution centers. |

| Footprint |

Space required for installation. |

Assess available warehouse space. |

Compact warehouses. |

| Flexibility |

Ability to handle different product types. |

Consider product variations. |

E-commerce and retail. |

| Integration |

Compatibility with existing systems. |

Review interface requirements. |

Automation in logistics. |

Identifying Your Warehouse Operational Requirements

When selecting the right robotic palletiser for your warehouse, understanding your operational requirements is crucial. Begin by assessing the volume of products you handle daily. This includes analyzing peak times and the types of products being palletised, such as their size, weight, and packaging. Understanding these factors will help determine the type of robotic palletiser that can efficiently manage your workload without causing bottlenecks or delays in your operation.

Additionally, consider the layout and available space in your warehouse. The design of your facility can significantly influence the choice of robotic palletiser. Narrow aisles may require compact systems that can maneuver easily, while larger spaces may allow for more extensive setups. It’s also important to evaluate the automation level desired within your warehouse. For instances where higher flexibility is essential, choose palletisers that can easily adapt to various product sizes and configurations, thereby enhancing overall operational efficiency.

Robotic Palletisers Selection Criteria

Evaluating Different Types of Robotic Palletisers

When evaluating different types of robotic palletisers for your warehouse needs, it's essential to understand the various classifications and their suitability for specific applications. Generally, robotic palletisers can be divided into three main categories:

articulated robots,

gantry robots, and

collaborative robots.

Articulated robots, known for their flexibility and dexterity, are ideal for operations requiring versatility in handling a variety of products and configurations. According to a report by MarketsandMarkets, the articulated robot segment is projected to grow with a CAGR of 12.3% from 2021 to 2026, reflecting their rising adoption in manufacturing processes.

On the other hand, gantry robots, which operate on a fixed path and are particularly effective for high-speed palletising, excel in environments where heavy loads and repetitive tasks are prevalent. A study by the International Federation of Robotics indicates that the use of gantry robots in palletising applications has seen a 15% increase in efficiency, leading to significant reductions in operational costs for warehouses focused on bulk handling.

Finally, collaborative robots, or cobots, are designed to work alongside human workers safely, providing an adaptive solution in scenarios where flexibility and space constraints are paramount. The increasing trend towards automation has led to a 35% growth in the cobot market, highlighting their growing importance in warehouse settings.

By understanding these differences and leveraging industry reports, businesses can make informed decisions on the type of robotic palletisers that align with their operational demands and investment strategies, ultimately enhancing efficiency and productivity in their warehouses.

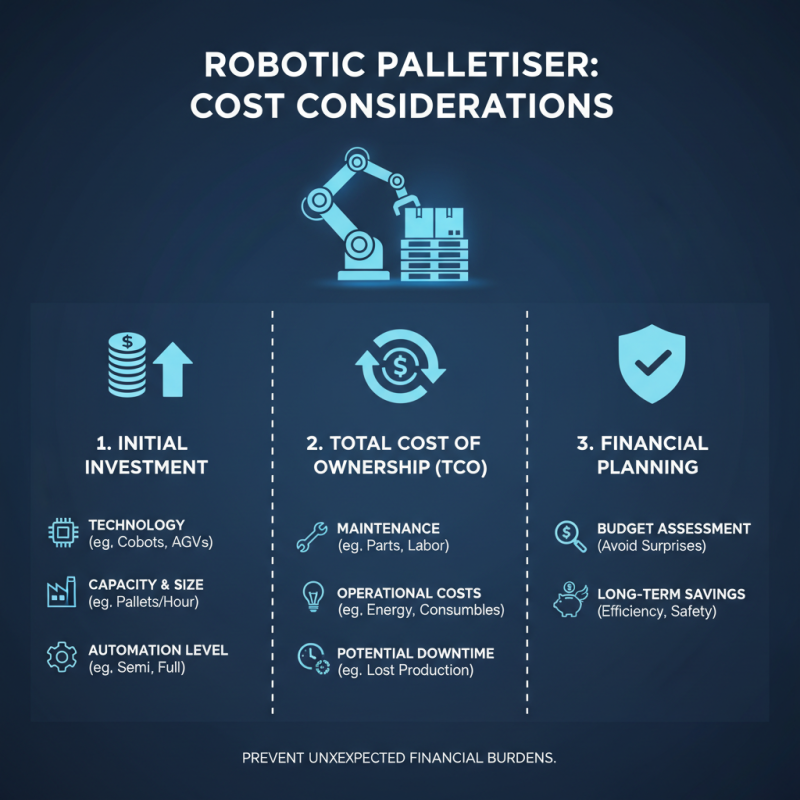

Assessing Budget and Cost Implications for Investment

When selecting robotic palletisers for your warehouse, it’s essential to thoroughly assess your budget and cost implications. Initial investment costs can vary widely based on the technology, capacity, and automation level required. It’s important to evaluate the total cost of ownership, which includes maintenance, operational costs, and potential downtime. Having a clear understanding of these factors will prevent unexpected financial burdens down the line.

Tip: Conduct a detailed cost-benefit analysis to weigh your options. Consider not only the purchase price but also the benefits of enhanced efficiency and productivity that a robotic palletiser can bring. Look into potential savings on labor costs and the reduction in product damage, as these can significantly offset the purchase price over time.

Furthermore, prioritize flexibility in your robotic palletising solution. As your warehouse operations evolve, you want a system that can adapt to changing product sizes and handling requirements without incurring substantial added costs. Investing in a scalable robotic palletising system might have a higher upfront cost, but it can lead to greater savings and efficiency in the long run.

Tip: Request quotes from multiple suppliers and ensure that you factor in possible future needs when assessing costs. Compare not just their pricing but also the support and training included in the purchase, as these can significantly impact your overall satisfaction and operational efficiency.

Considering Integration and Maintenance Support Options

When selecting the right robotic palletisers for your warehouse, it's crucial to consider not only the machinery's capabilities but also the integration and maintenance support options available. A recent industry report from the Robotic Industries Association indicates that warehouses that invest in automation technologies see a productivity increase of up to 30%. However, to fully realize these benefits, the selected robotic system must seamlessly integrate with existing processes and equipment. Evaluating the compatibility of the robotic palletiser with current warehouse management systems (WMS) and enterprise resource planning (ERP) solutions can significantly enhance operational efficiency.

Moreover, maintenance support is a critical aspect that should not be overlooked. Research shows that adequate maintenance can prolong a robotic palletiser's lifespan by 25% and reduce unexpected downtime. Organizations should inquire about the availability of training programs, remote support, and on-site service options from manufacturers. A proactive maintenance plan, including routine check-ups and timely software updates, can prevent costly disruptions. Thus, by prioritizing integration capabilities and ensuring robust maintenance support, warehouses can better position themselves to optimize performance and safeguard their investment in robotic automation technology.

Home

About Us

Products

Stranding & Bunching Machine

Extrusion Lines

Cable Packaging Machine

Automatic Cable Coil Strapping and Shrink Wrapping Machine

Automatic Cable Coiling and Wrapping Machine

Automatic Cable Coiling Machine with Microcomputer Control

Automatic Cable Spooling and Coiling Machine

Automatic Double Coiler

Cartesian Coordinate Palletizer

Circinate Film Cable Coil Automatic Packaging Machine

Film Heat Shrinking Machine

Robotic Palletizer

Auxiliary Equipment

Solution

News

Blog

Contact Us