The Ultimate Guide to Choosing Automated Palletizing Equipment for Your Business

In today's fast-paced industrial landscape, businesses are increasingly turning to Automated Palletizing Equipment to enhance efficiency and streamline operations. As logistics expert Dr. Emily Carter states, "The right automated palletizing solution not only saves time but also reduces labor costs, allowing companies to focus on growth and innovation." This insight encapsulates the transformative potential of automated systems, highlighting their role in modern supply chains.

Choosing the appropriate Automated Palletizing Equipment can be a daunting task for many organizations. With a variety of options available, understanding the specific needs of your operation is crucial. Factors such as product type, production volume, and facility layout play a significant role in determining the most suitable equipment. As businesses aim to optimize their processes, making informed decisions about automation becomes essential for long-term success.

In this ultimate guide, we will delve into the critical considerations for selecting the best Automated Palletizing Equipment for your business. From evaluating technological advancements to assessing return on investment, this comprehensive approach will guide you through the complexities of making the right choice in an ever-evolving industry.

Factors to Consider When Choosing Automated Palletizing Equipment

When choosing automated palletizing equipment for your business, several key factors must be taken into consideration to ensure you select the right solution that enhances efficiency and productivity.

First and foremost, evaluate the size and weight of the products you will be palletizing. Different machines have varying capacities and configurations to handle different weights and dimensions. Understanding your product specifications allows you to choose equipment that is best suited for the job, minimizing the risk of damage during the palletizing process.

Another critical factor to consider is the layout of your facility and the workflow requirements. Automated palletizers come in various designs, including robotic and conventional models, each with specific spatial needs. Assessing available floor space helps determine whether you require a compact unit or a more extensive system that can accommodate multiple functions. Additionally, consider the integration capabilities with your existing production lines and system compatibility to ensure seamless operation. Flexibility and scalability are also vital; as your business grows, your palletizing equipment should be able to adapt to changing needs without requiring a complete overhaul.

Types of Automated Palletizers: A Comprehensive Overview

When considering automated palletizers for your business, it's important to understand the various types available and how they can align with your operational needs.

Automated palletizers can be broadly classified into three categories: high-level, low-level, and robots.

High-level palletizers are typically used in applications where production rates are high. They stack products on a pallet from an elevated position, utilizing gravity to minimize manual handling, which can lead to increased efficiency and reduced labor costs. This type is ideal for large-scale operations requiring speed and throughput.

On the other hand, low-level palletizers work at ground level, bringing the pallet to the machine. This makes them particularly advantageous in industries where space is limited, or the need for quick changeovers is prevalent. They allow for easy integration with conveyor systems and are often tailored for specific products, optimizing the flow of goods.

Furthermore, robotic palletizers offer unparalleled flexibility, capable of handling a variety of products with intricate configurations. Their adaptability makes them suitable for businesses looking to automate without a significant investment in specialized equipment.

Each type of automated palletizer presents unique benefits, and the choice depends on factors such as the types of products being handled, production volume, and workspace constraints. Understanding the detailed functionalities of each option will empower businesses to make informed decisions that enhance efficiency and productivity in their operations.

Evaluating the Efficiency and Throughput of Palletizing Systems

When evaluating automated palletizing equipment, the efficiency and throughput of the system are critical factors that can significantly impact your business's operational performance. Efficiency encompasses how well the palletizing system uses resources, including labor and time, to maximize output. Key metrics such as cycle time, downtime, and the speed of product handling play a pivotal role in assessing overall efficiency. A highly efficient system not only reduces operational costs but also enhances productivity, allowing your business to meet growing demands with ease.

Throughput, on the other hand, refers to the amount of product that can be processed in a given time frame. This metric is crucial in determining whether a palletizing system can keep up with production volumes. When choosing equipment, it is essential to analyze the designed throughput relative to your production needs. Factors such as the type of products being palletized, the complexity of the pallet patterns, and the integration with existing processes should all be considered to ensure that the system can maintain consistent and high throughput levels. By focusing on both efficiency and throughput, businesses can ensure they select palletizing equipment that supports their growth and optimizes their supply chain operations.

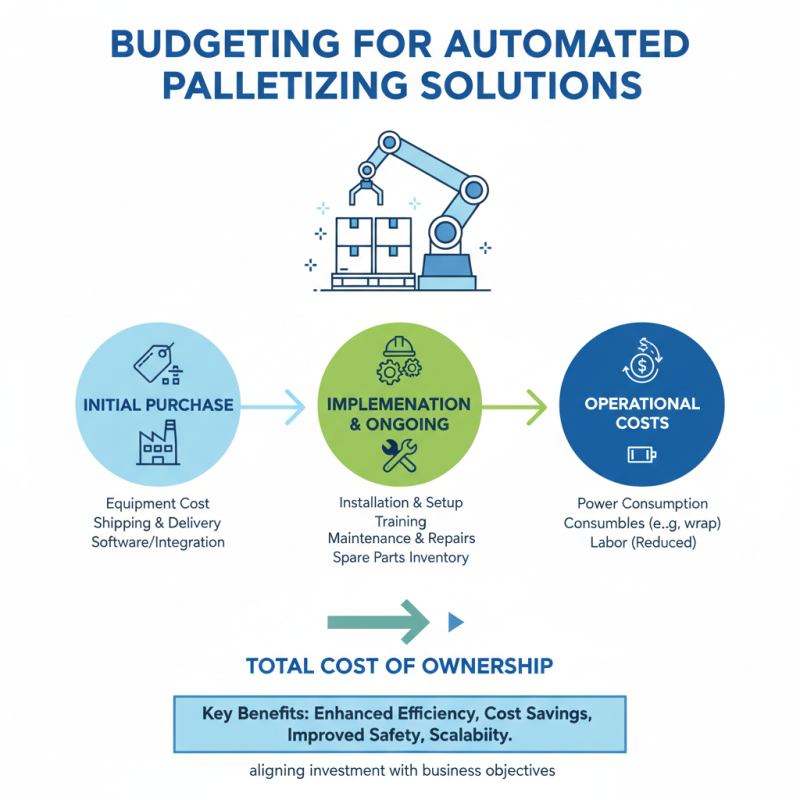

Cost Analysis: Budgeting for Automated Palletizing Solutions

Budgeting for automated palletizing solutions is a critical aspect of enhancing operational efficiency in any business. As you explore different automated palletizing equipment options, it is essential to analyze the total cost of ownership, which includes not just the initial purchase price but also installation, maintenance, and operational costs. Understanding these costs helps create a comprehensive budget and ensures that your investment aligns with your financial capabilities and business objectives.

When evaluating costs, consider various factors such as system complexity, throughput requirements, and the types of products being handled. More sophisticated palletizers may have higher upfront costs but can lead to significant savings in labor and increased productivity in the long run. It’s also crucial to account for potential cost variations based on features that enhance flexibility or scalability, as these can impact future expenses positively or negatively. Conducting a thorough cost analysis will provide valuable insights, allowing businesses to make informed decisions while ensuring that their automated palletizing system contributes optimally to their bottom line.

Maintenance and Support: Ensuring Longevity of Your Equipment

Maintenance and support are critical factors to consider when investing in automated palletizing equipment, as they directly impact the longevity and efficiency of your operations. According to a report by the Material Handling Industry (MHI), investing in proper maintenance can reduce equipment downtime by up to 25%. Regular preventive maintenance not only enhances performance but also prolongs the lifespan of machinery, with well-maintained systems often lasting 15-30% longer than neglected counterparts. This is particularly significant for businesses, as prolonged equipment life can significantly reduce replacement costs and improve overall return on investment.

Moreover, integrating a comprehensive support plan is essential for ensuring that your automated palletizing systems operate at peak efficiency. Industry studies suggest that up to 70% of production-related issues arise from improper handling and maintenance of equipment. Establishing a reliable service arrangement that includes training for staff, access to technical support, and a dedicated maintenance schedule is invaluable. As automation technology continues to advance, staying informed about emerging best practices in maintenance can help businesses adapt and optimize their equipment, reducing both the frequency and impact of equipment failures.

The Ultimate Guide to Choosing Automated Palletizing Equipment for Your Business - Maintenance and Support: Ensuring Longevity of Your Equipment

| Equipment Type |

Estimated Cost($) |

Maintenance Frequency |

Average Lifespan (Years) |

Support Availability |

| Robotic Arm |

$50,000 |

Monthly |

10 |

24/7 Support |

| Automated Stretch Wrapper |

$30,000 |

Quarterly |

7 |

Business Hours |

| Conveyor System |

$20,000 |

Bi-Annually |

15 |

Limited Hours |

| Palletizer |

$80,000 |

Monthly |

12 |

24/7 Support |

| Automated Guided Vehicle (AGV) |

$100,000 |

Monthly |

8 |

24/7 Support |

Home

About Us

Products

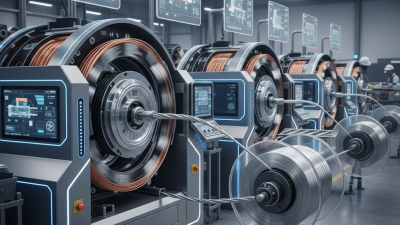

Stranding & Bunching Machine

Extrusion Lines

Cable Packaging Machine

Automatic Cable Coil Strapping and Shrink Wrapping Machine

Automatic Cable Coiling and Wrapping Machine

Automatic Cable Coiling Machine with Microcomputer Control

Automatic Cable Spooling and Coiling Machine

Automatic Double Coiler

Cartesian Coordinate Palletizer

Circinate Film Cable Coil Automatic Packaging Machine

Film Heat Shrinking Machine

Robotic Palletizer

Auxiliary Equipment

Solution

News

Blog

Contact Us