How to Choose the Best Automatic Plastic Wrapping Machine for Your Needs

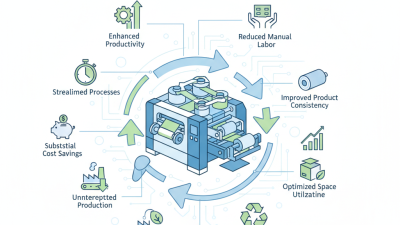

In the dynamic world of packaging, the significance of an Automatic Plastic Wrapping Machine cannot be overstated. According to recent industry reports, the global packaging machinery market is projected to reach $55 billion by 2025, with automatic machines seeing the largest growth due to their efficiency and versatility. As businesses strive to optimize operations and reduce labor costs, the adoption of automatic wrapping solutions has become increasingly prominent. Not only do these machines enhance packaging speeds, but they also ensure consistent product protection and presentation, which is crucial in today's competitive marketplace.

Choosing the right Automatic Plastic Wrapping Machine tailored to your specific business needs can significantly impact productivity and cost-effectiveness. The intricacies of machine specifications, such as wrapping speed, film type compatibility, and ease of use, are pivotal factors in making an informed decision. Industry research indicates that companies leveraging advanced wrapping technologies can improve their packing efficiency by up to 30%, underscoring the importance of selecting the right equipment. This guide will explore essential considerations and features to help you navigate the selection process effectively, ensuring that you invest in a machine that meets your operational requirements and enhances your packaging strategy.

Key Features to Consider in Automatic Plastic Wrapping Machines

When choosing the best automatic plastic wrapping machine, understanding the key features is essential for meeting your specific needs. First and foremost, consider the machine’s capacity and cutting speed. Depending on the volume of items you regularly wrap, you'll want a machine that can handle large quantities efficiently while maintaining a quick wrap cycle. Machines designed for higher throughput can help streamline your packing process, significantly reducing labor costs.

Another crucial aspect to examine is the machine’s versatility. Look for features such as adjustable film tension and different wrap styles to accommodate various shapes and sizes of products. A machine that offers multiple settings allows you to adapt to different packaging requirements without needing multiple machines, saving space and investment. Additionally, ease of operation is a fundamental attribute; user-friendly controls and automated settings can significantly enhance productivity, ensuring minimal downtime while your staff becomes accustomed to the machine.

Tip: Always evaluate the maintenance requirements of the machine. Regular upkeep can prolong its lifespan and ensure consistent performance, which ultimately contributes to overall efficiency. Moreover, consider machines that offer accessible customer support or service packages, as this can save you from prolonged disruptions in your operations due to technical issues.

Types of Automatic Plastic Wrapping Machines and Their Applications

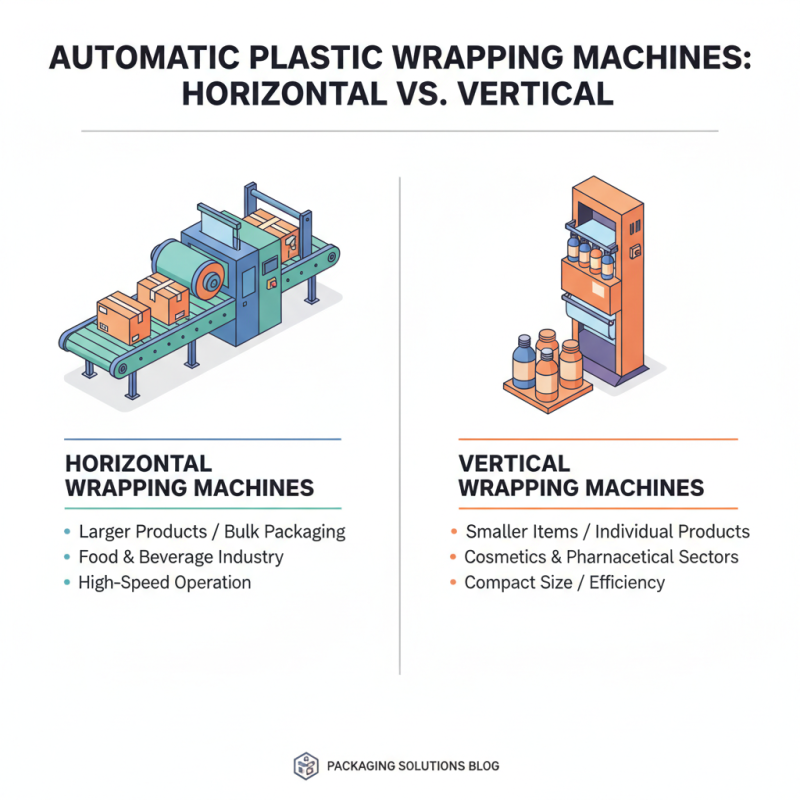

When selecting an automatic plastic wrapping machine, understanding the different types available and their applications is essential for optimizing your packaging process. The two most common types include horizontal and vertical wrapping machines. Horizontal machines are ideal for larger products and bulk packaging, often employed in industries like food and beverage, where high-speed operation is required. Conversely, vertical wrapping machines are designed for smaller items and are frequently used in the cosmetics and pharmaceutical sectors, benefiting from their compact size and efficiency in wrapping individual products.

According to a recent industry report by Smithers Pira, the global market for automatic packaging machines is projected to reach $45 billion by 2024, with a significant portion attributed to advancements in plastic wrapping technology. With improvements in automation and process efficiency, these machines can help companies meet increasing demand while maintaining high standards of product integrity. The choice of machine should also consider specific application needs, such as the type of material being wrapped and the level of automation desired, as these factors directly influence operational efficiency and cost-effectiveness.

Assessing Your Business Needs for Wrapping Efficiency and Speed

When selecting the best automatic plastic wrapping machine, understanding your business needs for wrapping efficiency and speed is crucial. The first step is to assess the volume of products you need to wrap daily. If your operation involves high throughput, a machine with advanced speed settings and automation features will be essential to maintain productivity. Additionally, consider the types of products being wrapped; varying shapes and sizes might require a machine with adjustable parameters to ensure a snug and secure wrap without waste.

Along with speed, it is important to evaluate wrapping efficiency regarding material usage and labor costs. A machine that minimizes film usage while maintaining a tight wrap can significantly reduce overhead expenses. Furthermore, look at the ease of operation and maintenance; a user-friendly interface will allow your team to operate the machine effectively, decreasing training time and potential for errors. An efficient machine not only streamlines the wrapping process but also enhances the overall workflow, contributing to a more productive business operation.

How to Choose the Best Automatic Plastic Wrapping Machine for Your Needs

| Feature |

Option 1 |

Option 2 |

Option 3 |

| Wrapping Speed (packs/min) |

30 |

50 |

70 |

| Film Width (mm) |

300 |

400 |

500 |

| Machine Dimensions (mm) |

1200 x 800 x 1500 |

1300 x 900 x 1600 |

1400 x 1000 x 1700 |

| Power Consumption (kW) |

1.5 |

2.0 |

2.5 |

| Weight (kg) |

200 |

250 |

300 |

Evaluating Budget and Cost-Effectiveness of Wrapping Machines

When evaluating the cost-effectiveness of automatic plastic wrapping machines, it's crucial to assess your budget parameters carefully. Start by determining the initial investment you can commit to the machine, including installation and training. Look for models that balance affordability with essential features that meet your specific needs.

Consider not only the purchase price but also ongoing operating costs such as maintenance, electricity, and the cost of wrapping materials. A machine that appears inexpensive at first may have higher long-term costs if it requires frequent repairs or consumes more power.

Tips: Always factor in the return on investment (ROI) when choosing a machine. Calculate how many hours you expect to save with an automatic system compared to manual wrapping, and translate that into labor cost savings. It may also be worthwhile to inquire about warranties and customer support services, as these can save money on repairs and downtime.

Additionally, explore leasing options or second-hand machines, which can greatly reduce your upfront costs while still providing the functionality you need. It's important to conduct a thorough analysis of your wrapping volume and frequency to ensure that you select a machine that would not just meet current demands but also accommodate future growth. This strategic approach will help you maximize your investment while ensuring seamless operations.

Maintenance and Support: Ensuring Longevity of Your Equipment

When investing in an automatic plastic wrapping machine, maintenance and support are crucial for ensuring the longevity of your equipment. Regular maintenance not only prolongs the life of your machine but also ensures that it operates at peak efficiency. It’s important to adhere to the manufacturer’s guidelines regarding routine checks and service intervals. This includes cleaning moving parts, checking for wear and tear, and ensuring that all components are properly lubricated.

Tips for maintenance include keeping the machine in a clean environment to prevent dust and debris buildup, which can affect its performance. Additionally, scheduling regular training sessions for staff to familiarize them with operational best practices and troubleshooting techniques can significantly reduce the need for professional repairs. Having a dedicated maintenance log can help track service dates and any issues that arise, making it easier to keep your machinery in optimal condition.

Moreover, consider establishing a relationship with a reliable support service to assist in addressing any issues promptly. A proactive approach to maintenance, combined with expert support, will go a long way in maximizing the lifespan and efficiency of your automatic plastic wrapping machine, ultimately leading to increased productivity and reduced operational costs.

Home

About Us

Products

Stranding & Bunching Machine

Extrusion Lines

Cable Packaging Machine

Automatic Cable Coil Strapping and Shrink Wrapping Machine

Automatic Cable Coiling and Wrapping Machine

Automatic Cable Coiling Machine with Microcomputer Control

Automatic Cable Spooling and Coiling Machine

Automatic Double Coiler

Cartesian Coordinate Palletizer

Circinate Film Cable Coil Automatic Packaging Machine

Film Heat Shrinking Machine

Robotic Palletizer

Auxiliary Equipment

Solution

News

Blog

Contact Us