-

Home

-

About Us

-

Products

-

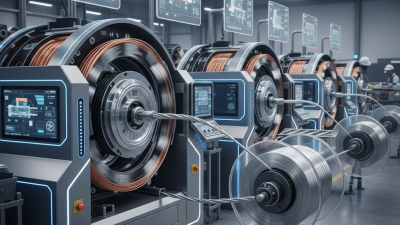

Stranding & Bunching Machine

-

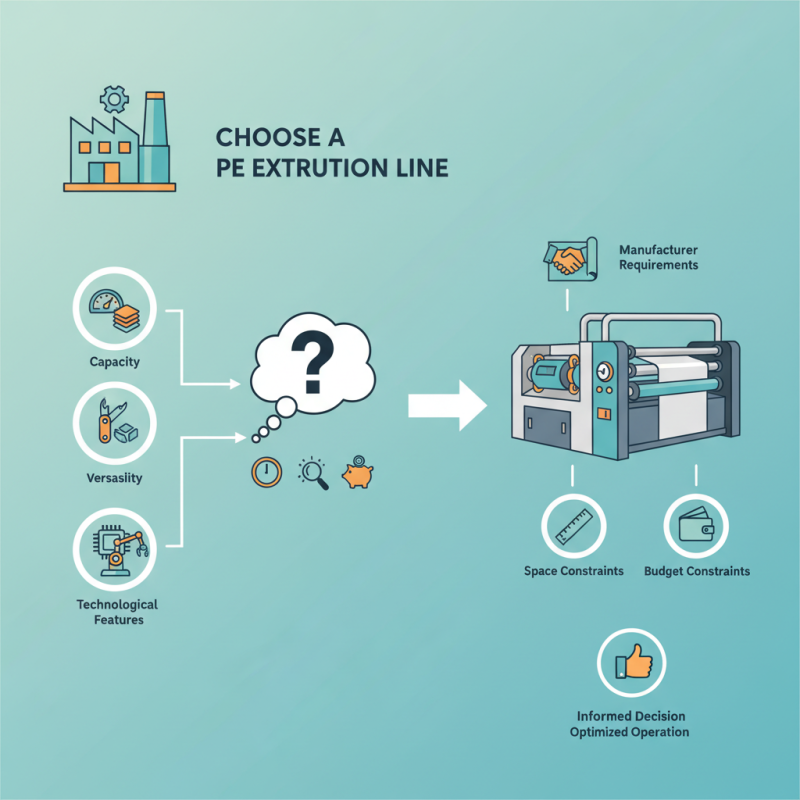

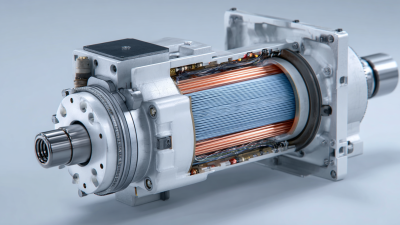

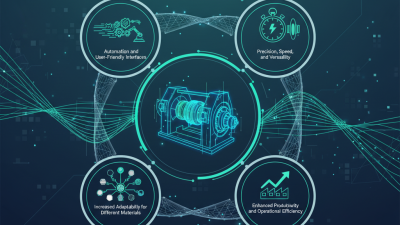

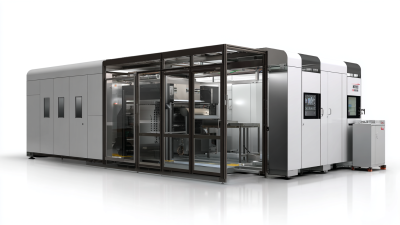

Extrusion Lines

-

Cable Packaging Machine

-

Automatic Cable Coil Strapping and Shrink Wrapping Machine

-

Automatic Cable Coiling and Wrapping Machine

-

Automatic Cable Coiling Machine with Microcomputer Control

-

Automatic Cable Spooling and Coiling Machine

-

Automatic Double Coiler

-

Cartesian Coordinate Palletizer

-

Circinate Film Cable Coil Automatic Packaging Machine

-

Film Heat Shrinking Machine

-

Robotic Palletizer

-

-

Auxiliary Equipment

-

-

Solution

-

News

-

Blog

-

Contact Us

Leave Your Message