How to Choose the Best Turret Rewinder for Your Needs?

Choosing the best Turret Rewinder is crucial for your business operations. Many factors come into play when making this decision. Quality, speed, and reliability are paramount. The right equipment can enhance productivity.

Understanding your specific needs is essential. Different models offer various features. Some prioritize speed, while others excel in precision. Consider your material type and volume. Analyze your workflow to identify your priorities.

Not all machines fit every situation. It’s vital to research and review options. Talk to industry peers and examine their experiences. This knowledge can guide your decision-making process. In the end, you want a Turret Rewinder that meets your demands and fits your budget. Balancing these elements is not always straightforward, but it’s worth the effort.

Understanding the Different Types of Turret Rewinders Available

When selecting a turret rewinder, it’s crucial to understand the types available. Turret rewinders are essential for various applications in the printing and packaging industry. They streamline the winding process, improving efficiency. According to recent industry reports, using the right turret rewinder can reduce downtime by 30%. This presents a significant opportunity for businesses focused on productivity.

There are two main types of turret rewinders: rotating and static. Rotating turrets move the roll while winding, which can be beneficial for heavy materials. Static rewinders hold the roll in place and rely on tension. Industry insights suggest that rotating models are preferred for high-volume production. However, they can be costly. Static models present a more budget-friendly option but may not support all materials effectively.

It’s also important to consider the rewinding capacity. Some machines handle larger rolls, while others are designed for smaller ones. Reports indicate that companies often choose machines based on a balance between capacity needs and cost. Overall, understanding these distinctions can significantly impact operational efficiency and overall cost-effectiveness in the long run. Each choice carries its own set of advantages and drawbacks. Choose wisely, as the wrong decision could lead to inefficiencies.

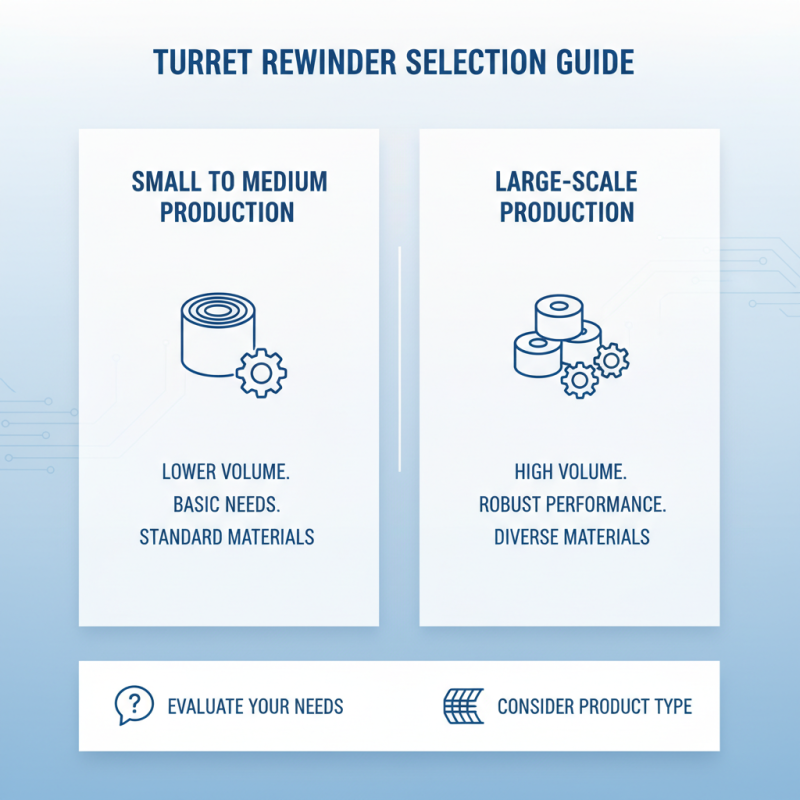

Comparison of Different Types of Turret Rewinders

Key Features to Consider When Choosing a Turret Rewinder

When selecting a turret rewinder, several key features deserve careful consideration. First, the size of the material rolls is crucial. Different applications require different roll diameters. Make sure the rewinder accommodates your specific needs. If it doesn’t, you might face operational inefficiencies.

Next, look into the speed ratings. A faster rewinder can improve productivity, but it may also raise the risk of errors. Find a balance between speed and precision. Additionally, consider the ease of use. Complex interfaces can lead to confusion. A clear, intuitive design is important for operators.

Another important aspect is the build quality. Rewinders are significant investments. A robust construction ensures longevity and minimizes maintenance. You might also want to reflect on the available features. Some models offer advanced controls, which can be valuable. However, too many features may complicate the operation. It’s vital to weigh these factors according to your production environment and staff capabilities.

Assessing the Cost vs. Benefits of Turret Rewinders

When considering turret rewinders, it’s crucial to assess the cost against the benefits they offer. A recent industry report indicates that businesses can reduce waste by up to 30% when using modern turret rewinders. This efficiency is significant in industries where material costs are high. Companies must evaluate how this cost-saving can offset the initial investment.

The upfront price of turret rewinders varies widely, usually ranging from $50,000 to over $150,000 based on features. However, a well-chosen model can lead to substantial long-term savings.

For instance, reducing labor costs by automating rewinding operations is a tangible benefit. A study showed that 50% of manufacturers who switched to turret rewinders reported improved productivity within the first six months.

Reflecting on operational needs is essential. Choosing a turret rewinder that matches production speeds and roll sizes is vital. Misalignment can lead to inefficiencies. Moreover, maintenance costs shouldn’t be overlooked. An inexpensive machine may cost more in repairs over time. Companies must think critically about their specific requirements and potential trade-offs when selecting the right turret rewinder.

Home

About Us

Products

Stranding & Bunching Machine

Extrusion Lines

Cable Packaging Machine

Automatic Cable Coil Strapping and Shrink Wrapping Machine

Automatic Cable Coiling and Wrapping Machine

Automatic Cable Coiling Machine with Microcomputer Control

Automatic Cable Spooling and Coiling Machine

Automatic Double Coiler

Cartesian Coordinate Palletizer

Circinate Film Cable Coil Automatic Packaging Machine

Film Heat Shrinking Machine

Robotic Palletizer

Auxiliary Equipment

Solution

News

Blog

Contact Us