What is a Concentric Stranding Machine and How Does it Work?

A Concentric Stranding Machine plays a crucial role in wire production. It enables the efficient stranding of multiple wires into a single composite cable. This process enhances electrical conductivity and mechanical strength.

Understanding how a Concentric Stranding Machine operates is essential for manufacturers. The machine arranges wires around a central core, often using precise layers. This layering technique improves overall performance and reliability.

While this technology offers many benefits, it’s not without challenges. Operators must be well-trained to manage the machine effectively. Mishandling can lead to defects in the wires. Additionally, maintenance should not be overlooked, as neglect can result in costly downtimes. The Concentric Stranding Machine is a remarkable tool that requires careful attention and technique.

What is a Concentric Stranding Machine?

A concentric stranding machine is a specialized device used to produce cables and wires. It twists strands of wire in a circular formation. This process creates a robust and flexible product that is ideal for various applications. The machine operates by feeding multiple wires through a series of twisting mechanisms.

The design is often quite intricate. Operators must monitor the alignment of wires closely. If the wires are not aligned properly, it can lead to uneven tension. This can result in weak spots in the final cable. Additionally, the machine's speed can affect the overall quality of the stranding process. A balance between speed and precision is essential but hard to achieve consistently.

Maintenance is a significant aspect of using these machines. Regular checks for wear and tear can help prolong their lifespan. Sometimes, the machine might produce unexpected outcomes. This can be frustrating for operators who aim for perfection. It's crucial to reflect on these challenges and develop better practices to mitigate such issues.

Principles of Operation of Concentric Stranding Machines

Concentric stranding machines play a crucial role in the manufacturing of cables and wires. They twist and layer wires in a concentric pattern to enhance their strength and flexibility. This process involves several fundamental principles that ensure the final product meets industry standards.

The machine operates using multiple spools. Each spool supplies wire that is twisted together in a precise manner. This creates a sturdy core with layers wrapped around it. Tension control is vital. If the tension is too high or too low, the wires can become misaligned or break. Operators need to monitor the machine closely. Small adjustments can lead to significant improvements or issues.

Additionally, the equipment employs sophisticated mechanics. A rotating drum or platform facilitates the stranding process. The speed of rotation significantly impacts the quality of the strand. It's a delicate balance to achieve consistency across the wires. Sometimes, despite the technology, imperfections occur. Operators must regularly inspect the output, noting areas that need refinement. Continuous improvement is essential in this field. Each cycle teaches valuable lessons about efficiency and precision.

Production Output of Concentric Stranding Machines (2023)

This bar chart illustrates the production output of concentric stranding machines over the course of 2023, showing an increasing trend in output as the year progresses.

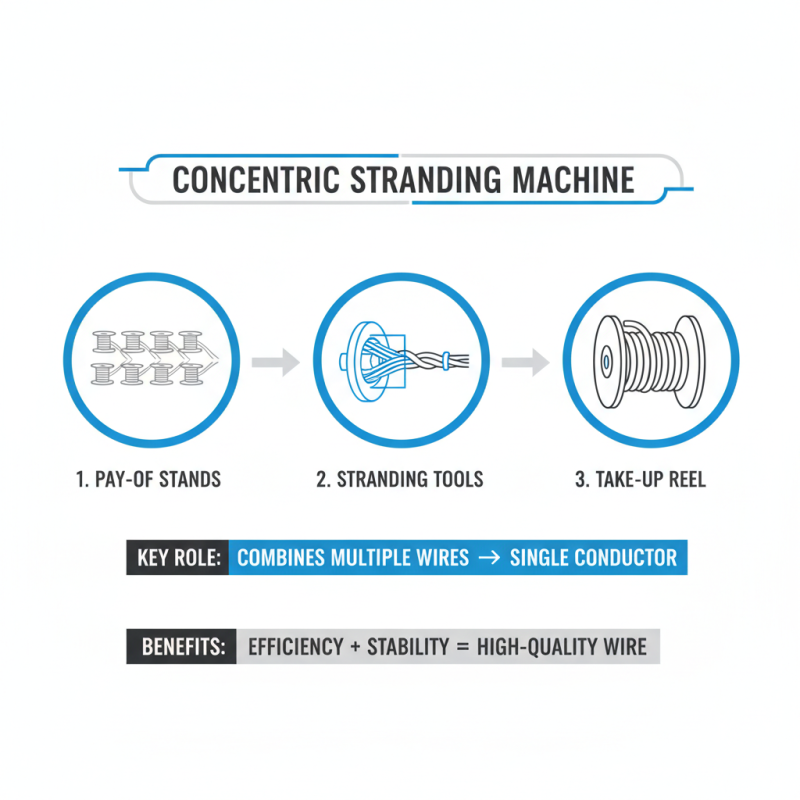

Key Components of a Concentric Stranding Machine

A concentric stranding machine plays a crucial role in wire and cable production. This equipment combines multiple wires into a single conductor, ensuring efficiency and stability. The main components of this machine are the pay-off stands, stranding tools, and the take-up reel. Each part works in harmony to produce high-quality stranded wire.

Pay-off stands hold the individual wires before they enter the stranding area. They must maintain precise tension. Industry reports indicate that improper tension can lead to production faults, decreasing overall efficiency by up to 15%. Stranding tools twist the wires together. These tools require careful calibration. If not set correctly, they can create uneven strands, affecting performance.

The take-up reel collects the finished product. Its design influences the final wire's reliability and durability. Research suggests that up to 20% of defects in electrical cables arise from improper handling during this stage. Operating a concentric stranding machine requires attention to detail. Each component significantly impacts the end product’s quality.

Applications of Concentric Stranding Technology

Concentric stranding technology plays a crucial role in various industries, particularly in cable manufacturing. This technique enhances electrical conductivity and mechanical durability. In recent years, the demand for wires and cables has surged, driven by the growth of renewable energy projects and telecommunications. Data from market research indicates that the global cable market is expected to reach $190 billion by 2025.

One key application of concentric stranding is in power cables. These cables require excellent flexibility and strength to withstand harsh environmental conditions. The concentric design helps mitigate issues like electromagnetic interference. For data cables, the stranding technique aids in enhancing signal integrity, making it ideal for high-speed internet.

Tips for manufacturers: Invest in high-quality materials. Conduct regular maintenance of stranding machines. Continuous training for operators is essential. Small errors in the manufacturing process can lead to significant defects down the line. Around 15% of produced cables fail quality tests, indicating room for improvement in processes.

Another interesting application is in the automotive industry. Electric vehicles rely heavily on advanced wiring systems. Concentric stranding allows for lighter cable designs without sacrificing performance. However, manufacturers should be wary of increasing production costs. Balancing quality and cost can be challenging but remains crucial for sustainability.

Advantages of Using Concentric Stranding Machines in Manufacturing

Concentric stranding machines are crucial in manufacturing processes. They twist multiple wires together to form a compact, efficient shape. This design allows for higher conductivity and flexibility. Many industries rely on these machines to produce high-quality cables and wires.

The advantages are significant. Concentric stranding reduces the overall size of cables, making them lighter and more manageable. This is particularly valuable in applications requiring space efficiency. Additionally, the twisting technique minimizes electromagnetic interference. As a result, products perform better in various environments.

Efficiency is another key benefit. These machines can operate at higher speeds without compromising quality. However, achieving perfect tension and alignment can be challenging. Manufacturers often must conduct regular maintenance to address wear and tear. The process is not flawless; it requires constant monitoring to ensure optimal performance.

What is a Concentric Stranding Machine and How Does it Work? - Advantages of Using Concentric Stranding Machines in Manufacturing

| Feature |

Description |

Advantages |

| Design |

Utilizes a concentric arrangement of wires |

Improves density and reduces insulation material |

| Efficiency |

High-speed operation with minimal downtime |

Increased production rates and lower labor costs |

| Flexibility |

Can produce various wire sizes and types |

Adaptable to different manufacturing needs |

| Quality Control |

Incorporates advanced monitoring systems |

Consistent product quality and reduced waste |

| Maintenance |

Requires specialized knowledge for upkeep |

Prolongs machine lifespan through proper care |

Home

About Us

Products

Stranding & Bunching Machine

Extrusion Lines

Cable Packaging Machine

Automatic Cable Coil Strapping and Shrink Wrapping Machine

Automatic Cable Coiling and Wrapping Machine

Automatic Cable Coiling Machine with Microcomputer Control

Automatic Cable Spooling and Coiling Machine

Automatic Double Coiler

Cartesian Coordinate Palletizer

Circinate Film Cable Coil Automatic Packaging Machine

Film Heat Shrinking Machine

Robotic Palletizer

Auxiliary Equipment

Solution

News

Blog

Contact Us