Top Features of Double Twist Bunching Machine You Should Know in 2025

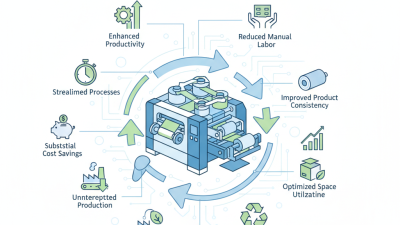

As the demand for efficient and high-quality production processes continues to grow, the Double Twist Bunching Machine emerges as a vital solution in various industries. By 2025, advancements in technology and design will further enhance the capabilities of this essential equipment, making it a cornerstone for manufacturers seeking to optimize their operations. The Double Twist Bunching Machine is specifically engineered to deliver precision, speed, and versatility, enabling businesses to streamline their production lines while maintaining superior quality.

Understanding the top features of the Double Twist Bunching Machine is crucial for industries looking to remain competitive in a rapidly evolving market. As we delve into its key attributes, we will explore how innovations in automation and user-friendly interfaces, coupled with increased adaptability for different materials, position this machinery as a game-changer. By elucidating these characteristics, companies can make informed decisions about integrating this technology into their production processes, ultimately enhancing productivity and operational efficiency.

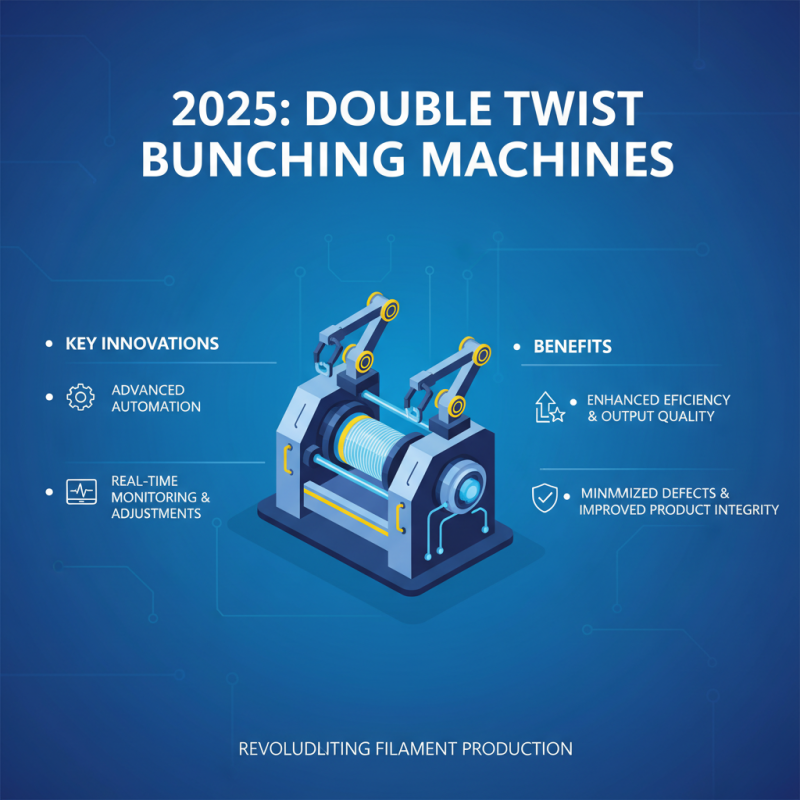

Key Innovations in Double Twist Bunching Machines for 2025

In 2025, double twist bunching machines (DTBMs) are set to revolutionize the manufacturing process of various filament products, thanks to key innovations designed to enhance efficiency and output quality. One of the standout features is the integration of advanced automation technologies that streamline the operation, allowing for real-time monitoring and adjustments. This automated system ensures a consistent tension and twist during the bunching process, minimizing the risk of defects and improving overall product integrity.

Additionally, 2025 will see the introduction of smart technology within DTBMs, enabling predictive maintenance capabilities. These machines will utilize sensors and analytics to monitor their condition and performance continuously, alerting operators before potential issues arise. Such innovations not only reduce downtime but also extend the lifespan of the machinery. Furthermore, enhanced energy efficiency measures will be implemented, driving down operational costs while promoting sustainable practices in production. This combination of automation, smart technology, and energy efficiency positions double twist bunching machines as indispensable assets for modern manufacturing.

Enhanced Automation Features in Upcoming Double Twist Bunching Models

The upcoming models of double twist bunching machines are set to revolutionize the industry with their enhanced automation features. As manufacturers strive for greater efficiency and productivity, these machines will integrate advanced technology to streamline operations. With capabilities such as automatic thread feeding and real-time monitoring systems, users can expect a significant reduction in manual interventions. This level of automation not only minimizes the risk of human error but also allows operators to focus on higher-level tasks, ultimately boosting overall productivity.

Additionally, the new double twist bunching machines will incorporate smart sensors and adaptive control systems, enabling them to adjust settings dynamically based on material properties and production requirements. This means that as new materials are introduced or as product specifications change, these machines will automatically recalibrate to maintain optimal performance. The integration of data analytics will further empower operators by providing insights into machine performance and maintenance needs, allowing for proactive measures that minimize downtime. As these advancements unfold in 2025, the future of double twist bunching technology is poised to enhance production capabilities immensely.

Top Features of Double Twist Bunching Machine in 2025

This chart displays the anticipated features of Double Twist Bunching Machines in 2025, highlighting improvements in automation, efficiency, and ease of use.

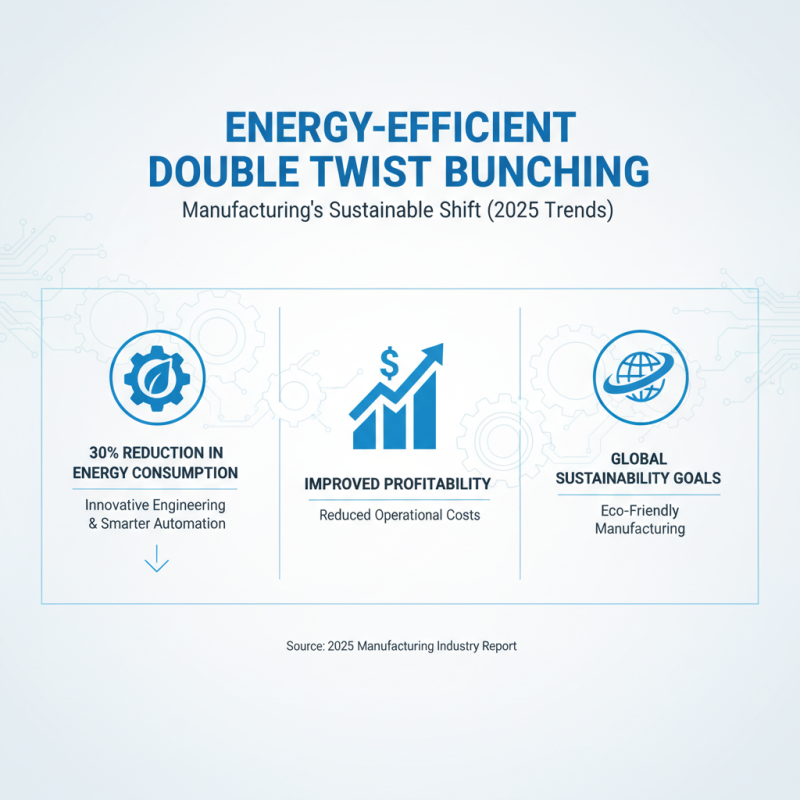

Energy Efficiency Improvements in Double Twist Bunching Technologies

The double twist bunching machine (DTBM) has gained significant traction in manufacturing processes, particularly due to its advancements in energy efficiency. In 2025, companies are increasingly focused on optimizing their operations, and the energy improvements in double twist bunching technologies illustrate this shift. Recent studies indicate that DTBMs have reduced energy consumption by up to 30%, thanks to innovative engineering techniques and smarter automation systems. These improvements are not only benefiting the bottom line but also aligning manufacturers with global sustainability goals.

Moreover, a report published by the International Energy Agency (IEA) in early 2024 highlighted that energy-efficient machinery could contribute to a potential savings of over $200 billion annually across the manufacturing sector. The adoption of DTBMs equipped with energy-efficient motors and advanced control systems enables manufacturers to not only cut down on operational costs but also minimize their environmental impact. With a growing emphasis on sustainable practices, the double twist bunching machine stands out as a pivotal technology that embodies the industry’s move toward greener manufacturing solutions, ensuring a more responsible and efficient production environment in the years to come.

User-Friendly Interface Enhancements for Double Twist Bunching Machines

In 2025, the advancements in user-friendly interfaces for Double Twist Bunching Machines have taken center stage in enhancing operational efficiency. The latest models are designed with intuitive touchscreens that allow operators to easily navigate through various functions, significantly reducing training time for new users. These interfaces feature clear visual prompts and step-by-step guidance, streamlining the setup process and ensuring that even those with minimal technical expertise can operate the machinery with confidence.

Additionally, the introduction of customizable dashboards has become a game-changer in machine operation. Users can now tailor their display screens to prioritize the metrics and settings most relevant to their specific tasks. This level of personalization not only boosts productivity by minimizing the need to sift through unnecessary information but also facilitates real-time monitoring of performance indicators. As a result, operators can quickly make adjustments to optimize the production process, ensuring both efficiency and quality in the final output.

Advanced Safety Mechanisms in 2025 Double Twist Bunching Models

The advancements in technology have significantly enhanced the safety mechanisms in double twist bunching machines for 2025. One of the key improvements lies in the incorporation of intelligent monitoring systems that detect potential hazards in real-time. These systems utilize a combination of sensors and AI algorithms to predict and mitigate risks associated with the operation of the machine. By continuously analyzing variables such as temperature, vibration, and load, these mechanisms can alert operators to any anomalies, thereby preventing accidents and ensuring a safer working environment.

Another crucial feature is the enhanced emergency stop functionalities. The 2025 models come equipped with highly responsive emergency stop buttons that are easily accessible from multiple locations around the machine. This design allows operators to quickly halt the operation in case of an emergency, minimizing the risk of injury. Furthermore, advanced safety interlocks ensure that critical components remain inoperable if certain safety parameters are not met, promoting a culture of safety and awareness in the workplace. These innovations not only protect operators but also contribute to overall efficiency, as they reduce downtime caused by accidents and facilitate smoother operations.

Top Features of Double Twist Bunching Machine You Should Know in 2025 - Advanced Safety Mechanisms in 2025 Double Twist Bunching Models

| Feature |

Description |

Benefit |

| Automatic Stop Mechanism |

Activates when a fault is detected, preventing damage. |

Increases machine longevity and reduces maintenance costs. |

| Emergency Shutoff |

Easily accessible switch to shut down operations instantly. |

Enhances user safety and quick response in emergencies. |

| User-friendly Interface |

Touchscreen controls for easy operation and monitoring. |

Reduces training time and increases operational efficiency. |

| Safety Guards |

Physical barriers that prevent direct access to moving parts. |

Minimizes risk of accidents and injuries during operation. |

| Overheat Protection |

Sensors that monitor temperature and shut down if overheating occurs. |

Prevents fires and damages due to overheating. |

Home

About Us

Products

Stranding & Bunching Machine

Extrusion Lines

Cable Packaging Machine

Automatic Cable Coil Strapping and Shrink Wrapping Machine

Automatic Cable Coiling and Wrapping Machine

Automatic Cable Coiling Machine with Microcomputer Control

Automatic Cable Spooling and Coiling Machine

Automatic Double Coiler

Cartesian Coordinate Palletizer

Circinate Film Cable Coil Automatic Packaging Machine

Film Heat Shrinking Machine

Robotic Palletizer

Auxiliary Equipment

Solution

News

Blog

Contact Us