The Ultimate Guide to Palletizing Robot Applications in Modern Warehouses

In the rapidly evolving landscape of modern warehouses, the significance of automation has reached unparalleled heights, with palletizing robot applications taking center stage. As industry expert Dr. John Smith, a leading authority on robotic automation in logistics, aptly puts it, "The integration of palletizing robots is not just a trend; it is a revolution that simplifies operations and enhances efficiency." With the demand for rapid and reliable logistics solutions growing, these automated systems are transforming the way goods are handled, stored, and shipped.

Palletizing robots are engineered to tackle the labor-intensive task of stacking and organizing products, providing significant advantages in speed, accuracy, and safety. They are designed to work tirelessly, effectively reducing human error and increasing throughput. By implementing these advanced technologies, warehouses are not only optimizing their operations but also freeing up human resources to focus on more strategic tasks.

As we delve into the myriad applications of palletizing robots, it becomes clear that their role in modern warehousing is indispensable. From food and beverage industries to pharmaceuticals and beyond, the versatility and reliability of these robotic solutions are paving the way for a future where efficiency and productivity are paramount.

Understanding Palletizing Robots: Definition and Functions

Palletizing robots have become a cornerstone of efficiency in modern warehouses, significantly impacting productivity and operational costs. By definition, a palletizing robot is an automated machine designed to load and stack products onto pallets in a systematic and organized manner. Their core functions include picking, placing, and arranging various items, which drastically reduces the need for manual labor. According to a report by the International Federation of Robotics (IFR), the market for industrial robots, including palletizing solutions, grew by 12% in 2022, with projections estimating a compound annual growth rate (CAGR) of 14% through 2024.

One of the primary advantages of palletizing robots is their ability to handle a wide range of products, which can enhance the overall workflow in a warehouse setting. These robots utilize advanced vision systems and AI algorithms to optimize their operations, ensuring that they can adapt to different shapes, sizes, and weights of items. Research indicates that implementing robotic systems can lead to a 20-30% increase in throughput efficiency, allowing warehouses to process more orders with fewer errors. Furthermore, companies that invest in automation can experience a return on investment (ROI) in as little as 12 months, reinforcing the value of integrating palletizing robots into warehouse operations.

Key Benefits of Implementing Palletizing Robots in Warehouses

The implementation of palletizing robots in modern warehouses offers significant benefits that enhance operational efficiency and productivity. According to recent market analysis, robotic palletizers are becoming essential as businesses increasingly demand automation solutions to keep up with fast-paced logistics operations. These robots can perform repetitive tasks around the clock, drastically reducing labor costs while minimizing human error. A report indicated that automated systems can improve productivity by up to 20-30%, a critical advantage in today's competitive environment.

Tips: When implementing palletizing robots, consider starting with a pilot program to assess their impact on your operations. This allows for adjustments before full-scale implementation. Additionally, choose robotic systems that offer easy integration with existing warehouse management systems to streamline processes.

Moreover, advancements in artificial intelligence and machine learning are revolutionizing how palletizing robots operate. These technologies enable robots to adapt to various load configurations, enhancing their flexibility. The evolution of palletizing solutions aligns with the growing trend of automated fulfillment centers, which are projected to continue rising as businesses seek to improve supply chain resilience and performance. By investing in these technologies, companies can better position themselves to meet increasing consumer demands and adapt to market fluctuations.

The Ultimate Guide to Palletizing Robot Applications in Modern Warehouses - Key Benefits of Implementing Palletizing Robots in Warehouses

| Feature |

Benefit |

Impact on Warehouse Operations |

Implementation Time |

| Increased Efficiency |

Higher throughput rates |

Reduces bottlenecks and speeds up order fulfillment |

1-3 months |

| Consistent Quality |

Minimizes errors in palletizing |

Improves product safety and reduces returns |

2-4 months |

| Labor Savings |

Reduces dependence on manual labor |

Allows human workers to focus on higher-value tasks |

3-6 months |

| Flexibility |

Can handle various pallet sizes and configurations |

Adapts to changing product lines and seasonal demands |

2-5 months |

| Enhanced Safety |

Reduces workplace injuries |

Improves overall worker satisfaction and retention |

1-3 months |

Types of Palletizing Robots: Differences and Use Cases

In modern warehouses, palletizing robots have become essential in optimizing storage and improving operational efficiency. When selecting a palletizing robot, it’s important to understand the various types available and their specific use cases. The two main categories are articulated robots and gantry robots. Articulated robots, with their flexible arms, can handle a wide variety of products and configurations. This makes them ideal for industries with diverse product lines, such as food and beverage or consumer goods. Conversely, gantry robots excel in handling high volumes of uniform items, making them suitable for e-commerce and logistics companies needing rapid deployment and precision.

Tips: When choosing a palletizing robot, consider the weight and size of the products being handled. Larger items may require a robot with a higher weight capacity, while smaller, lightweight products can benefit from a faster, more agile robot. Additionally, assess the layout of your warehouse; modular systems may save space and facilitate scaling operations in the future.

Another important distinction is the end-of-arm tooling, which varies according to the type of products being palletized. Vacuum grippers are commonly used for bags and boxes, while claw grippers are ideal for misshaped products. Ensuring the right tooling can enhance efficiency and reduce waste during the palletizing process. Always evaluate the specific requirements of your application to select the most effective robot type and configuration.

Integration of Palletizing Robots with Warehouse Management Systems

The integration of palletizing robots with warehouse management systems (WMS) is revolutionizing the way modern warehouses operate. By automating the palletizing process, businesses can significantly enhance their operational efficiency and reduce labor costs. The WMS serves as the brain of warehouse operations, orchestrating various tasks, including inventory management, order processing, and logistics coordination. When palletizing robots are seamlessly integrated, they enable real-time data exchange, allowing for better tracking of stock levels, faster response times to changing demand, and optimal allocation of resources.

Moreover, this integration creates a cohesive workflow that minimizes errors associated with manual handling. For example, WMS can communicate with palletizing robots to provide precise instructions based on current orders and inventory statuses. This dynamic interaction not only ensures that products are correctly assembled onto pallets but also that they are strategically organized for efficient outbound logistics. By leveraging advanced algorithms and machine learning capabilities within the WMS, warehouses can anticipate needs and automate decision-making processes, resulting in a more streamlined, efficient operation that is crucial for competing in today’s fast-paced market.

Future Trends in Palletizing Robot Technology and Automation

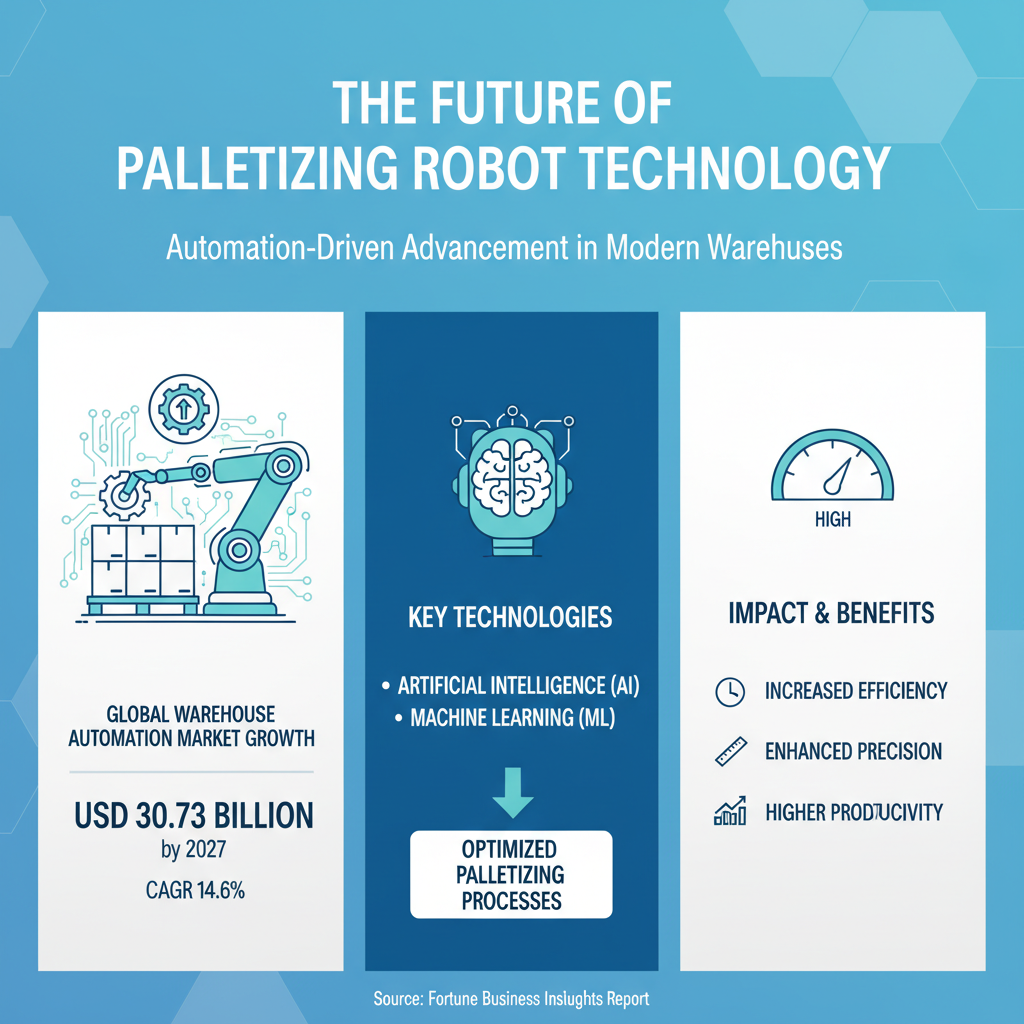

As modern warehouses continue to evolve, the future of palletizing robot technology is poised for significant advancements driven by automation.

According to a report by Fortune Business Insights, the global warehouse automation market is expected to reach $30.73 billion by 2027, growing at a CAGR of 14.6%.

This surge in demand reflects the increasing need for efficiency and precision in logistics operations, where palletizing robots play a crucial role.

Advanced technologies, such as artificial intelligence and machine learning, are enabling these robots to optimize palletizing processes by learning from past data and adjusting their actions in real time, thus enhancing productivity.

Moreover, the integration of collaborative robots (cobots) is expected to reshape the palletizing landscape.

A study from Research and Markets indicates that the cobot market is projected to grow significantly, reaching $12 billion by 2025.

These robots can work alongside human operators, improving safety and flexibility in warehouse environments.

With the ability to handle various payloads and adapt to different tasks, cobots are becoming essential in the efficient management of warehouse operations, further driving the trend toward automation.

As technology continues to develop, the combination of robotic automation and collaborative systems will redefine how palletizing processes are executed, maximizing both efficiency and output in modern warehouses.

Home

About Us

Products

Stranding & Bunching Machine

Extrusion Lines

Cable Packaging Machine

Automatic Cable Coil Strapping and Shrink Wrapping Machine

Automatic Cable Coiling and Wrapping Machine

Automatic Cable Coiling Machine with Microcomputer Control

Automatic Cable Spooling and Coiling Machine

Automatic Double Coiler

Cartesian Coordinate Palletizer

Circinate Film Cable Coil Automatic Packaging Machine

Film Heat Shrinking Machine

Robotic Palletizer

Auxiliary Equipment

Solution

News

Blog

Contact Us