Ultimate Tips for Choosing Tmg Palletizer for Your Needs?

The industry of palletizing is rapidly evolving, with Tmg Palletizer leading the charge. Recent reports indicate that the global palletizer market is projected to grow by over 10% annually. Experts suggest that automation will drive this surge, with Tmg's technology at the forefront. According to John Smith, a noted authority in automation, "A well-chosen Tmg Palletizer can significantly boost productivity and efficiency."

It’s crucial for businesses to select equipment that fits their unique needs. Tmg Palletizers offer flexibility, catering to various product types. However, some companies struggle with the selection process. They often overlook specific features that could enhance performance. Finding the right balance between cost and capability is essential.

When investing in a Tmg Palletizer, consider not just current needs but future scalability. Reports suggest that companies with adaptable systems fare better in changing markets. Yet, assessing long-term value can be tricky. It’s vital to account for maintenance and operational costs. Ultimately, understanding your requirements is key to making an informed choice.

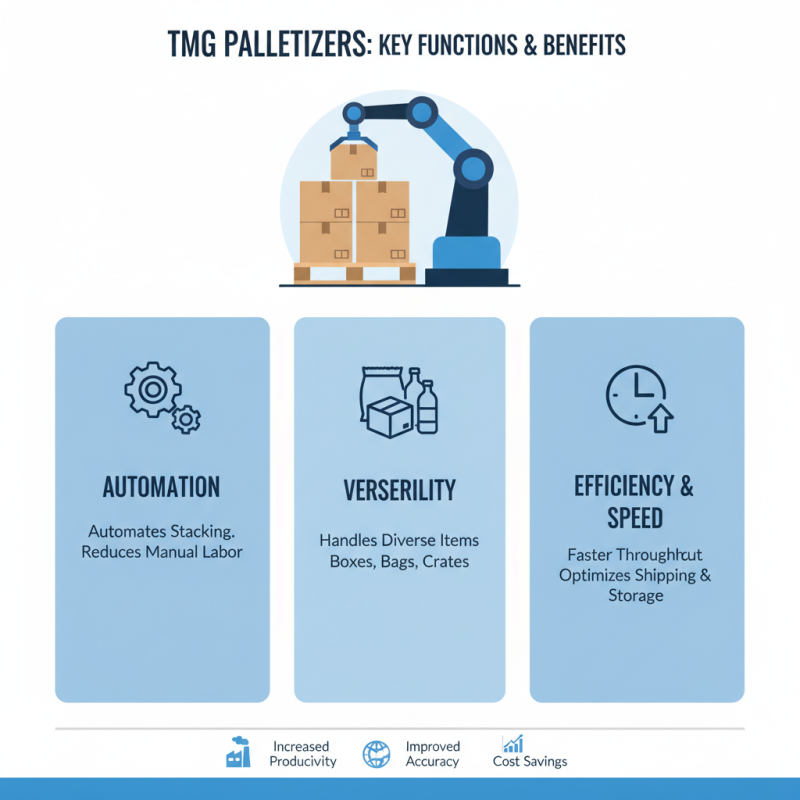

Understanding the Basics of Tmg Palletizers and Their Functions

When considering Tmg palletizers, understanding their basic functions is crucial. These machines automate the process of stacking products onto pallets. They can handle a variety of items, such as boxes and bags. The main goal is to enhance efficiency in shipping and storage. You’ll find that many models offer different features and capabilities.

Choosing the right palletizer involves knowing your needs. Consider the types of products you’ll be working with. Think about their weights and sizes. Not all palletizers are suitable for every product type. This mismatch can lead to inefficiencies. It’s essential to assess the space you have available as well. Limited space might restrict your options, so plan accordingly.

Here’s a tip: always evaluate the machine's capacity. Ensure it meets your production volume. That way, you won’t face bottlenecks later. Another important point is machine compatibility. Check how it integrates with existing systems. Poor integration can lead to workflow problems. Keep these aspects in mind for a smoother operational experience.

Assessing Production Volume Requirements for Tmg Palletizer Selection

When selecting a TMG palletizer, assessing your production volume is crucial. According to recent industry reports, companies operating with a production volume of over 500 units per hour often find fully automated palletizers more efficient. These machines can reduce labor costs and increase throughput. However, for lower volumes, a semi-automatic option might suffice. This can save initial investment costs while still meeting production needs.

One report highlights that 30% of companies overestimate their output requirements. They've invested in high-capacity systems that remain underutilized. This reflects the importance of accurate volume assessment. Analyze your actual production data. Look for patterns in demand. If there's significant variability, a scalable solution might be more appropriate.

Another key detail to consider is the type of product being palletized. Fragile items could need more gentle handling. A machine suited for end-of-line packaging may struggle with delicate products. Striking the right balance between speed and care is crucial for maintaining product integrity. Use industry benchmarks as starting points, but adapt them to your specific context.

Evaluating Technical Specifications: Speed, Capacity, and Footprint

When choosing a TMG palletizer, evaluating technical specifications is essential. Speed, capacity, and footprint play critical roles in operational efficiency. According to a recent industry report, an average palletizer operates at speeds of 1,500 to 2,500 products per hour. However, not all facilities require high-speed operations. Understanding your production needs is vital.

Tips: Consider the types of products you handle. Are they bulky or delicate? The palletizer must match your product's characteristics. Capacity should align with your daily output. For instance, a small factory might require a device with a capacity of 40-60 pallets per hour. In contrast, large-scale operations may need over 100 pallets per hour.

Footprint is another critical factor. Palletizers come in various sizes. A compact design may be necessary for limited floor space. Yet, larger models might provide better efficiency for robust systems. An ideal design will use the workspace effectively while ensuring optimal performance. Reflecting on your operational layout can help identify the perfect fit.

Ultimate Tips for Choosing Tmg Palletizer for Your Needs

| Model |

Speed (Cycles per Minute) |

Capacity (Units per Hour) |

Footprint (LxW in mm) |

Power Requirements (kW) |

| Model A |

20 |

1200 |

1500 x 1200 |

5.5 |

| Model B |

25 |

1500 |

1600 x 1300 |

6.0 |

| Model C |

18 |

1100 |

1400 x 1100 |

4.5 |

| Model D |

30 |

1800 |

1700 x 1400 |

7.0 |

Analyzing Industry Standards and Compliance for Tmg Palletizers

When selecting a Tmg palletizer, industry standards must be at the forefront of your decision-making. Compliance with regulations ensures safety and efficiency. Consider how well each machine adheres to regulatory guidelines. This can affect both your workflow and product quality. Lack of compliance can lead to expensive fines or operational delays.

Evaluate the performance metrics of the palletizer you are considering. Pay attention to the speed, capacity, and flexibility. Choosing a model that fits well with your production line is essential. You must think about your specific needs. Does the palletizer handle various load sizes? Can it adapt to changes in your production?

Tip: Always request detailed performance reports. This will help you make an informed choice. Don’t forget to factor in the maintenance requirements, too. Some machines may look appealing at first but require frequent repairs. This can disrupt your production cycle. Reflecting on these aspects will lead you to a better decision.

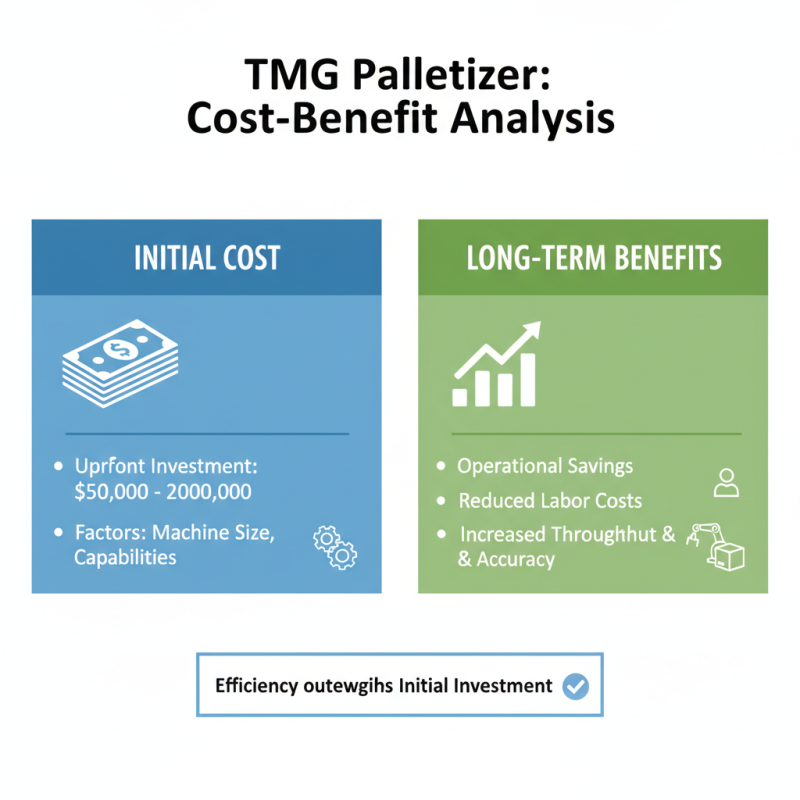

Comparing Costs: Initial Investment vs. Long-Term Efficiency Benefits

When considering a TMG palletizer, it's essential to analyze the initial costs against long-term efficiency benefits. The upfront investment can be significant, often ranging from $50,000 to $200,000. Factors like machine size and capabilities directly impact pricing. However, a deeper look into operational savings can reshape this perspective.

A report by the Food Industry Association indicates that automating palletizing can reduce labor costs by up to 30%. This reduction translates to savings of thousands each month. Moreover, automated systems typically improve throughput by 20-25%. With these rates, even a higher initial investment becomes justifiable.

Maintenance costs are another important aspect. Industry data suggest maintenance needs decrease by about 15% with a well-chosen system. This results in fewer downtimes. However, choosing the wrong model may lead to unexpected breakdowns, ultimately increasing costs. Evaluating all these factors is crucial. Understanding your production flow will help align your choice with your long-term efficiency goals.

Home

About Us

Products

Stranding & Bunching Machine

Extrusion Lines

Cable Packaging Machine

Automatic Cable Coil Strapping and Shrink Wrapping Machine

Automatic Cable Coiling and Wrapping Machine

Automatic Cable Coiling Machine with Microcomputer Control

Automatic Cable Spooling and Coiling Machine

Automatic Double Coiler

Cartesian Coordinate Palletizer

Circinate Film Cable Coil Automatic Packaging Machine

Film Heat Shrinking Machine

Robotic Palletizer

Auxiliary Equipment

Solution

News

Blog

Contact Us