Top 10 Tips for Efficiently Managing Rewinding Line Operations

Efficient management of Rewinding Line operations is crucial for optimizing productivity and minimizing waste in manufacturing processes. According to the latest industry reports, a well-managed rewinding line can increase throughput by as much as 20%, significantly impacting the overall efficiency of production systems. With the rising demand for high-quality, precision-engineered products, manufacturers are increasingly focusing on refining their rewinding processes to meet consumer expectations while controlling costs.

One of the common challenges faced in the operation of Rewinding Lines is downtime caused by equipment failures or inefficient workflows. The manufacturing sector consistently reports that unplanned downtime can account for up to 16% of total production time, leading to significant financial losses. Implementing proactive maintenance strategies and effective operational practices can mitigate these risks, ensuring smoother and more consistent production flows.

To empower managers and operators in overcoming these challenges, we present the top 10 tips for efficiently managing Rewinding Line operations. By adopting these strategies, companies can not only enhance their operational efficiency but also contribute to sustainable manufacturing practices, thereby maintaining a competitive edge in an ever-evolving market landscape.

Understanding the Basics of Rewinding Line Operations

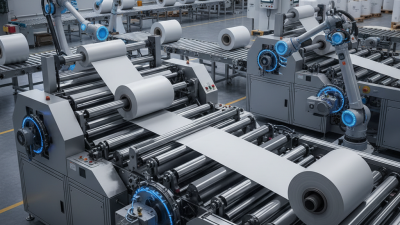

Rewinding line operations are essential for various industries where materials are processed, converted, and packaged. Understanding these operations begins with recognizing their key components: the unwinding section, the rewinding mechanism, and the control systems that oversee the entire process. The unwinding area is where raw materials, typically in rolls, are fed into the system. Properly managing this phase ensures a smooth transition to the rewinding process, reducing waste and increasing efficiency.

Once the materials pass through the unwinding section, they are typically aligned and processed through various machinery before being rewound onto smaller rolls or packaged for distribution. A thorough understanding of the mechanics involved, such as tension control, speed adjustments, and quality checks, is crucial. Effective training of personnel to operate these machines and familiarity with troubleshooting can significantly minimize downtime. Moreover, implementing routine maintenance schedules helps maintain optimal functionality, ensuring that the rewinding lines operate smoothly and efficiently. By focusing on these foundational aspects, operators can enhance performance and reliability in their rewinding line operations.

Identifying Key Performance Indicators for Efficiency

Key performance indicators (KPIs) are crucial for evaluating the efficiency of rewinding line operations. By focusing on specific metrics, organizations can identify areas for improvement and ensure optimal performance. According to the "Manufacturing Efficiency Report 2022," the average efficiency rate in the rewinding sector hovers around 75%. To surpass this benchmark, it's essential to monitor KPIs such as throughput time, downtime, and waste percentage.

Throughput time measures the total time taken from raw material to finished product, impacting overall productivity. A study revealed that reducing throughput time by just 10% can lead to an increase in annual production capacity by 17%, significantly enhancing profit margins. Additionally, tracking downtime—often caused by mechanical failures or operational delays—allows teams to implement preventive maintenance strategies, which have been shown to reduce unexpectedly high downtime rates by up to 30%. Waste percentage also plays a critical role; ISO reports indicate that minimizing waste can lead to cost savings of 5-10% for manufacturing operations annually.

By systematically analyzing these KPIs, companies can make informed decisions that not only enhance the efficiency of rewinding line operations but also contribute to sustainable practices. As industry standards continue to evolve, setting benchmarks for these metrics will ensure that organizations remain competitive and adaptive in a rapidly changing market.

Top 10 Tips for Efficiently Managing Rewinding Line Operations

This chart displays the efficiency of different key performance indicators (KPIs) in rewinding line operations, helping to identify areas for improvement.

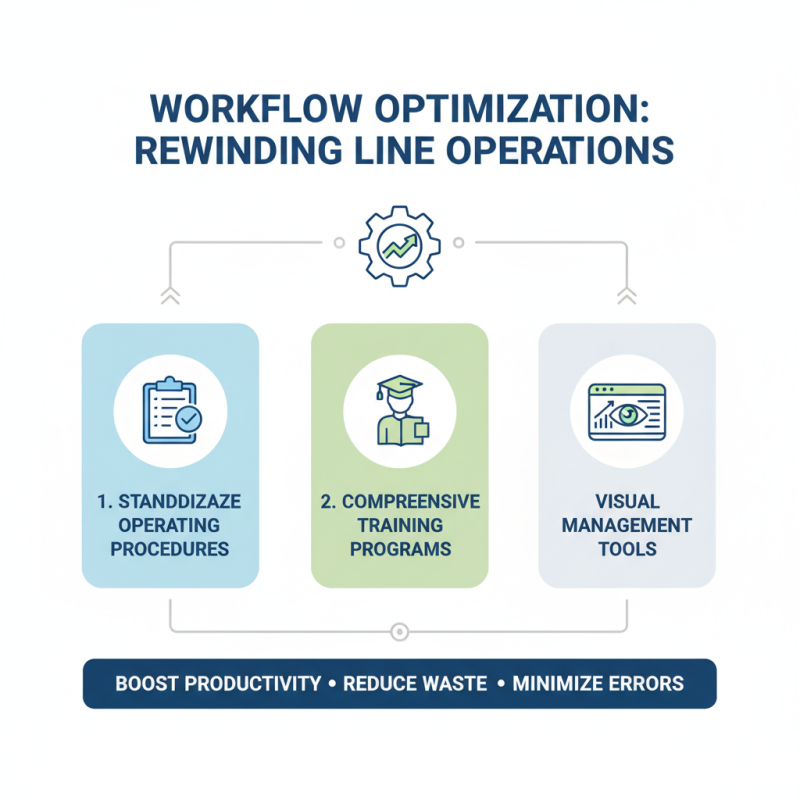

Implementing Best Practices for Workflow Optimization

Implementing best practices for workflow optimization in rewinding line operations requires a strategic approach to enhance productivity and reduce waste. One key practice is to standardize operating procedures, ensuring that each team member is familiar with their roles and responsibilities. By developing a comprehensive training program, employees can efficiently navigate the equipment and processes, minimizing errors that lead to downtime. Furthermore, visual management tools, such as process flowcharts and performance dashboards, can provide real-time feedback, allowing operators to quickly identify bottlenecks and adjust workflows as necessary.

Another important aspect of workflow optimization is the integration of data analytics to monitor performance metrics. By collecting data on production output, machine efficiency, and defect rates, managers can make informed decisions that enhance operations. Identifying patterns and trends through analytics helps in proactively addressing issues before they escalate. Additionally, fostering a culture of continuous improvement encourages team members to suggest enhancements for the process, empowering them to take ownership of their work and contribute to the overall effectiveness of the line. These practices not only streamline the operational flow but also promote a more engaged and responsive workforce.

Training and Engaging Staff for Improved Performance

A crucial aspect of efficiently managing rewinding line operations is the training and engagement of staff. Investing in comprehensive training programs not only equips employees with the necessary skills but also fosters a deeper understanding of the machinery and processes involved. Hands-on training sessions that simulate real operational scenarios can enhance staff confidence and competence, enabling them to troubleshoot issues and optimize workflows more effectively. Additionally, providing regular workshops and refresher courses ensures that staff remain up-to-date with industry standards and technological advancements, which significantly contributes to overall operational efficiency.

Engagement is equally critical in maximizing performance. Encouraging open communication and feedback creates a collaborative environment where employees feel valued and motivated. Implementing team-building activities and recognizing individual and collective achievements can boost morale and strengthen teamwork. Moreover, establishing clear goals and involving employees in decision-making processes fosters ownership and accountability. When staff are engaged and feel invested in their work, they are more likely to strive for excellence and contribute to continuous improvement in the rewinding line operations.

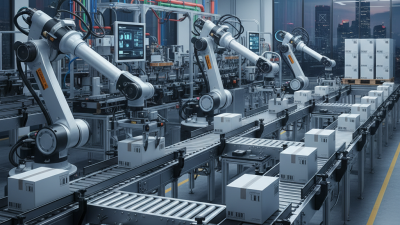

Leveraging Technology for Enhanced Rewinding Line Management

In today's fast-paced manufacturing environment, leveraging technology is crucial for enhancing the efficiency of rewinding line operations. The adoption of smart automation tools allows operators to streamline processes, reduce manual labor, and minimize errors. By integrating advanced control systems and real-time monitoring, businesses can optimize production schedules and manage workflow more effectively. These technologies not only enhance operational visibility but also enable quicker responses to any disruptions, thereby increasing overall productivity.

Moreover, data analytics plays a pivotal role in modern rewinding line management. By collecting and analyzing performance data, companies can identify patterns and potential bottlenecks in their operations. This information allows for informed decision-making, leading to continuous improvement and greater efficiency. Additionally, predictive maintenance systems can be employed to foresee equipment failures before they occur, significantly reducing downtime and maintenance costs. Embracing these technological advancements not only positions businesses to adapt to evolving market demands but also fosters a culture of innovation within the workforce.

Top 10 Tips for Efficiently Managing Rewinding Line Operations - Leveraging Technology for Enhanced Rewinding Line Management

| Tip Number |

Tip Description |

Technology Utilized |

Expected Outcome |

| 1 |

Implement Real-Time Monitoring |

IoT Sensors |

Improved efficiency and reduced downtime |

| 2 |

Utilize Automated Rewinding Systems |

Automation Software |

Reduced manual labor and increased throughput |

| 3 |

Integrate Data Analytics |

Data Analytics Tools |

Enhanced decision-making based on data |

| 4 |

Incorporate Predictive Maintenance |

Machine Learning Algorithms |

Minimized unexpected breakdowns |

| 5 |

Implement Quality Control Technologies |

Vision Systems |

Increased product quality and consistency |

| 6 |

Use of Cloud-Based Platforms |

Cloud Software |

Enhanced collaboration and data access |

| 7 |

Regular Staff Training and Development |

E-Learning Platforms |

Higher workforce efficiency |

| 8 |

Enhance Line Layout for Optimal Flow |

Simulation Software |

Increased productivity and reduced waste |

| 9 |

Adopt a Centralized Control System |

SCADA Systems |

Streamlined operations with better visibility |

| 10 |

Increase Inter-Departmental Communication |

Collaboration Tools |

Enhanced workflow and project management |

Home

About Us

Products

Stranding & Bunching Machine

Extrusion Lines

Cable Packaging Machine

Automatic Cable Coil Strapping and Shrink Wrapping Machine

Automatic Cable Coiling and Wrapping Machine

Automatic Cable Coiling Machine with Microcomputer Control

Automatic Cable Spooling and Coiling Machine

Automatic Double Coiler

Cartesian Coordinate Palletizer

Circinate Film Cable Coil Automatic Packaging Machine

Film Heat Shrinking Machine

Robotic Palletizer

Auxiliary Equipment

Solution

News

Blog

Contact Us