2025 Top 10 Tubular Stranding Machines for Enhanced Wire Performance

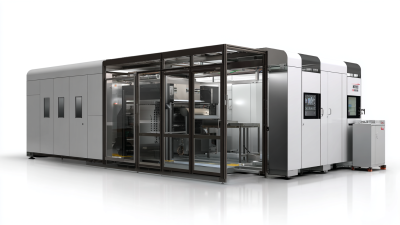

In the ever-evolving landscape of wire manufacturing, the significance of advanced machinery cannot be overstated. At the forefront of this technological revolution is the Tubular Stranding Machine, a pivotal tool that enhances wire performance and productivity. As we look towards 2025, it becomes essential to identify the top ten tubular stranding machines that not only meet industry standards but also drive innovation in wire production. These machines are designed to optimize the stranding process, ensuring that wires exhibit superior flexibility, strength, and durability.

The upcoming selection of the best tubular stranding machines will be guided by several key factors, including operational efficiency, adaptability to various wire materials, and ease of integration with existing production lines. Additionally, this guide will delve into practical tips for maximizing the potential of these machines, ensuring manufacturers can leverage the benefits effectively. From automated systems that enhance precision to energy-efficient solutions that minimize costs, the right tubular stranding machine can significantly elevate the quality of wire products, paving the way for advancements across multiple sectors.

Stay tuned as we explore the top contenders that promise to reshape the future of wire manufacturing.

Innovative Features of 2025's Top Tubular Stranding Machines

In 2025, the top tubular stranding machines are set to revolutionize wire performance with innovative features designed for enhanced efficiency and precision. These advanced machines incorporate state-of-the-art technology, such as real-time monitoring systems and AI-driven adjustments, allowing for seamless operation under varying conditions. Manufacturers are focusing on integrating high-speed capabilities while maintaining a low operational cost, empowering businesses to increase production without compromising quality.

Tip: When selecting a tubular stranding machine, consider models with customizable settings to match your specific production needs. This flexibility can significantly reduce waste and improve product consistency.

Moreover, safety features are a critical part of these machines. Enhanced guarding systems and emergency shutdown protocols not only protect operators but also contribute to maintaining uninterrupted productivity. Some models even offer remote diagnostics, enabling quick troubleshooting and minimizing downtime for maintenance.

Tip: Always ensure that the machine you choose complies with the latest safety standards and provides adequate training for all operators to take full advantage of its features. This will foster a safer and more efficient working environment.

Comparative Analysis of Performance Metrics in Top 5 Stranding Machines

In the realm of wire manufacturing, selecting the right stranding machine can significantly impact overall wire performance. A comparative analysis of the top 5 tubular stranding machines reveals key performance metrics that can guide industry professionals in making informed decisions. According to a recent report by the International Wire & Cable Association (IWCA), machines featuring a high-speed throughput of over 2000 meters per minute can enhance productivity by 30%, allowing manufacturers to meet rising market demands efficiently.

Moreover, precision in stranding and reduced scrap rates are critical metrics highlighted in the analysis. Machines that incorporate advanced tension control systems demonstrated a reduction in scrap rates by nearly 15%, as noted in a study published in the Journal of Material Processing Technology. This is essential for maintaining cost-effectiveness while producing high-quality wire products. As manufacturers strive for excellence, focusing on these performance metrics will be pivotal in selecting the most suitable tubular stranding solutions for enhanced wire performance.

Impact of Tubular Stranding Technology on Wire Durability

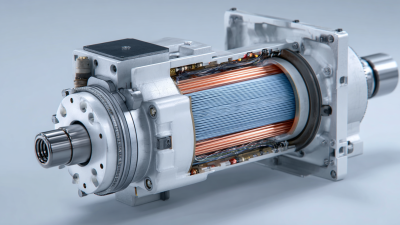

The impact of tubular stranding technology on wire durability is profound and multifaceted. Tubular stranding machines, designed specifically for the manufacturing of high-performance wires, utilize a unique approach that enhances the structural integrity of the wire by minimizing the risk of deformation during the stranding process. By employing a tubular setup, these machines ensure that the strands are uniformly tensioned and evenly distributed, which reduces the chances of weak points that can lead to premature failure.

Moreover, the innovative design of tubular stranding machines facilitates improved material handling and processing. The precision achieved in the stranding process not only boosts the overall quality of the wire but also contributes to its resilience against environmental stresses such as temperature fluctuations and corrosion. Consequently, wires produced with advanced tubular technology exhibit longer lifespans and enhanced performance under demanding conditions, making them ideal for a range of applications from telecommunications to power transmission. This progressive evolution in stranding machinery therefore plays a pivotal role in advancing wire durability, ensuring that products meet the increasingly stringent demands of modern industry.

2025 Top 10 Tubular Stranding Machines for Enhanced Wire Performance

| Machine Model |

Stranding Capacity (kg/h) |

Number of Strands |

Motor Power (kW) |

Wire Diameter Range (mm) |

Technology Features |

| Model A |

150 |

36 |

30 |

0.5 - 3.0 |

Automated tension control, low energy consumption |

| Model B |

200 |

48 |

40 |

0.6 - 2.5 |

High-speed operation, precise stranding |

| Model C |

120 |

30 |

25 |

0.4 - 2.0 |

Compact design, user-friendly interface |

| Model D |

180 |

64 |

45 |

0.5 - 3.5 |

Flexible configurations, robust performance |

| Model E |

140 |

40 |

32 |

0.5 - 2.8 |

State-of-the-art control systems, high efficiency |

| Model F |

160 |

54 |

38 |

0.5 - 3.2 |

Advanced lubrication system, quiet operation |

| Model G |

170 |

62 |

42 |

0.6 - 3.0 |

Customizable setups, enhanced safety features |

| Model H |

190 |

40 |

50 |

0.5 - 3.4 |

Optimized cooling system, low maintenance |

| Model I |

130 |

32 |

27 |

0.4 - 2.2 |

User-friendly control panel, compact footprint |

| Model J |

155 |

38 |

36 |

0.5 - 2.9 |

Efficiency monitoring, quick setup changes |

User Reviews and Industry Feedback on Leading Stranding Machines

In the competitive landscape of wire manufacturing, user reviews and industry feedback play a crucial role in the selection of tubular stranding machines. As per the latest industry report by MarketsandMarkets, the global market for stranding machines is projected to reach USD 1.2 billion by 2025, reflecting a CAGR of 5.4%. Users are increasingly drawn to machines that not only enhance performance but also optimize operational efficiency.

Among the top-rated models are the Brand A and Brand B stranding machines, praised for their advanced technology and user-friendly interfaces. Feedback indicates that Brand A's innovative tension control system significantly reduces wire breakage, contributing to a 15% increase in output quality when compared to traditional machines.

Similarly, Brand B's energy-efficient design appeals to eco-conscious manufacturers, with reported energy savings of up to 30%. Such insights underscore the importance of aligning machine selection with user expectations and industry trends, fostering increased innovation in wire performance enhancement.

Future Trends in Tubular Stranding Machine Development and Efficiency

The development of tubular stranding machines is witnessing rapid advancements, primarily driven by the need for enhanced efficiency and wire performance. According to a recent industry report by TechNavio, the tubular stranding machine market is projected to grow at a CAGR of 5.2% from 2023 to 2028, reflecting a robust demand for innovative solutions in wire manufacturing. Manufacturers are focusing on automation and precision engineering to improve production output while ensuring high-quality wire strands. These advancements not only increase operational efficiency but also reduce material waste, which is a critical aspect in today's sustainability-focused industrial landscape.

Tip: For manufacturers looking to upgrade their machines, consider investing in models equipped with smart technology features that allow for real-time monitoring and data analysis. This type of machinery can significantly enhance operational efficiency by predicting maintenance needs and reducing downtime.

In addition to automation, the integration of high-speed technology is transforming the tubular stranding process. A survey conducted by the International Wire and Cable Symposium revealed that companies implementing high-speed stranding technology reported a 30% reduction in cycle time, showcasing a significant improvement in productivity. As manufacturers continue to adapt to these future trends, the focus will shift towards developing machines that not only meet current industry standards but also anticipate future demands for flexibility and performance.

Tip: Explore partnerships with technology providers to leverage cutting-edge developments in tubular stranding machinery and stay ahead in the competitive market.

Home

About Us

Products

Stranding & Bunching Machine

Extrusion Lines

Cable Packaging Machine

Automatic Cable Coil Strapping and Shrink Wrapping Machine

Automatic Cable Coiling and Wrapping Machine

Automatic Cable Coiling Machine with Microcomputer Control

Automatic Cable Spooling and Coiling Machine

Automatic Double Coiler

Cartesian Coordinate Palletizer

Circinate Film Cable Coil Automatic Packaging Machine

Film Heat Shrinking Machine

Robotic Palletizer

Auxiliary Equipment

Solution

News

Blog

Contact Us