2026 How to Use a Concentric Stranding Machine Effectively?

The efficient operation of a Concentric Stranding Machine is vital in the wire and cable industry. According to a 2022 industry report by GlobalWire Insights, effective stranding can improve production efficiency by up to 35%. This highlights the importance of mastering this technology. Michael Thompson, a noted expert in the field, once stated, "Maximizing the output of a Concentric Stranding Machine requires precision and understanding of material dynamics."

A well-tuned Concentric Stranding Machine can significantly reduce waste and improve product quality. However, inefficiencies can still creep in. Operators must be vigilant about machine settings and material feed rates. Regular maintenance is crucial. Neglecting these details may lead to increased downtime and operational costs. Studies show that improperly set machines can lead to defects in up to 15% of produced cables.

Incorporating best practices is essential for optimal performance. While many companies have adopted cutting-edge technologies, understanding the fundamental workings of a Concentric Stranding Machine remains critical. Continuous learning and adaptation are necessary. A commitment to quality will keep production on track and ensure the long-term success of operations in this competitive landscape.

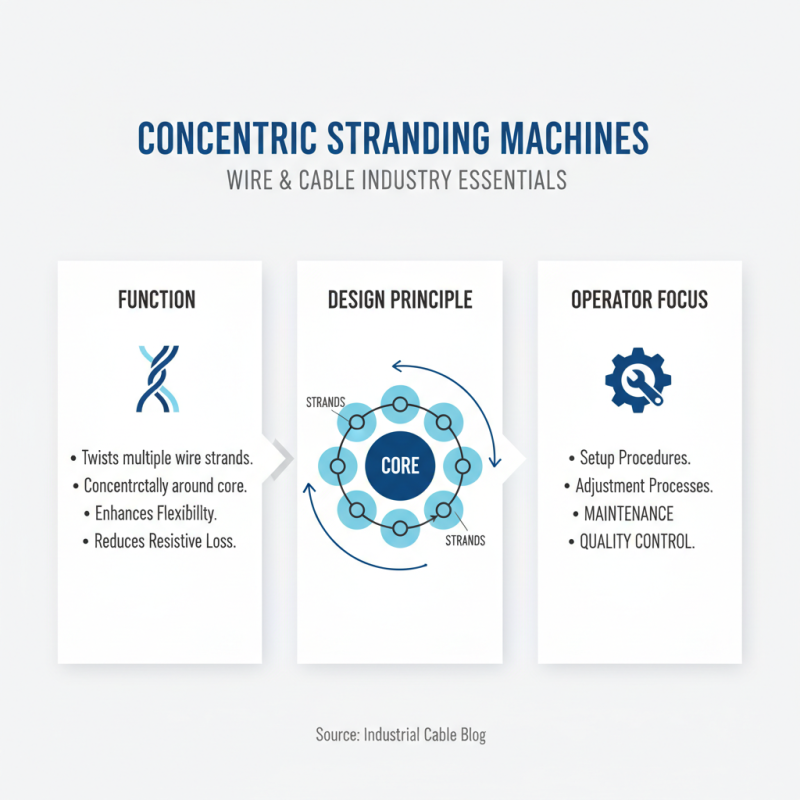

Understanding the Basics of Concentric Stranding Machines

Concentric stranding machines are crucial in the wire and cable industry. Understanding their basics is vital for effective use. These machines twist multiple strands of wire concentrically around a central core. This design enhances the wire's flexibility and reduces resistive loss. Operators must be familiar with the machine’s setup and adjustment processes.

Tips for effective use include regularly checking the tension settings. Uneven tension can lead to poor stranding quality. Adjusting the pay-off and take-up devices is also important. Ensure that spools rotate smoothly to avoid interruptions. Operators should always inspect the wires before starting the process. Look for any visible defects or inconsistencies.

Some operators may overlook the importance of regular maintenance. Neglecting this can lead to machine wear and tear, affecting performance. Run preventive checks often. Address any unusual noises or vibrations immediately. Remember, investing time in understanding the machine will save time later. Effective stranding relies on both the use of technology and operator skill.

Key Components and Their Functions in Stranding Machines

In the world of wire production, the concentric stranding machine plays a pivotal role. Its key components each contribute significantly to the overall efficiency of the stranding process. Central to this machine is the rotating drum, which houses the wire and enables uniform tension. Data suggests that optimal tension can reduce wire maturity defects by up to 30%.

Another critical component is the payout system. This system ensures a steady flow of wire, preventing interruptions during production. Industry reports indicate that a well-calibrated payout reduces variability, achieving within 5% tolerance on the strand diameter. Effective use of the payout system boosts productivity, but operators must remain vigilant to avoid misalignments.

Finally, a reliable control system monitors the entire operation. This system provides real-time feedback, enabling operators to adjust parameters instantly. Yet, many overlook the need for regular software updates. Outdated controls can lead to inefficiencies, causing a production drop of 15% or more. Understanding these components can help operators enhance performance and address potential issues proactively.

2026 Concentric Stranding Machine Components: Effectiveness Analysis

Step-by-Step Operating Procedures for Effective Use

Operating a concentric stranding machine effectively requires attention to detail. Following a clear set of procedures can significantly enhance the results. Start with a thorough inspection of the machine. Check all components for signs of wear or damage. This initial step is important but often overlooked. Sometimes, minor issues lead to bigger problems during operation.

Next, prepare the materials. Ensure that the wires are correctly fed into the machine. Misalignment can cause tangling or inconsistent stranding. Adjust the tension settings according to the type of wire being used. It's easy to forget these adjustments, leading to poor output quality. Keep an eye on the spool as it rotates. An uneven feed can ruin the entire process.

As you begin operation, monitor the process closely. Look out for any unusual noises or hesitations. These can be indicators of deeper issues. Regularly check the stranding pattern for consistency. If something seems off, pause the operation. It’s better to pause and investigate than to continue and produce defective products. Reflect on the adjustments you made. Learning from each session will guide future operations to be even smoother.

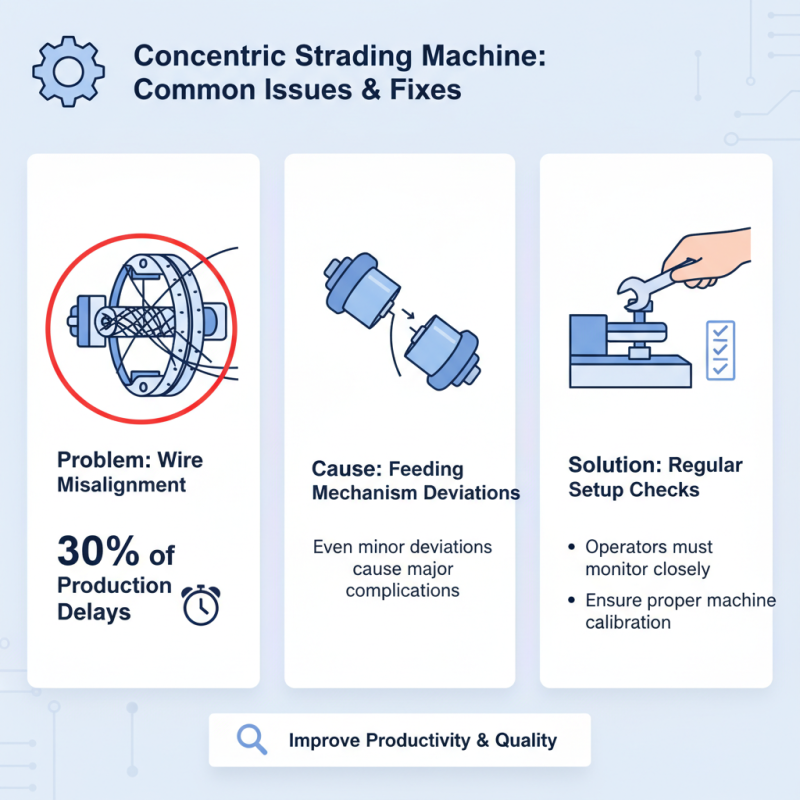

Common Issues and Troubleshooting Tips

When using a concentric stranding machine, common issues can arise that impact productivity and quality. One frequent problem is misalignment of wires during the stranding process. Research shows that nearly 30% of production delays are due to misalignment issues. Regular checks of the machine's setup are crucial. Operators should monitor feeding mechanisms closely, as even minor deviations can lead to significant complications.

Another challenge is the inconsistent tension in the wires. Studies have indicated that proper tension is essential for uniform stranding. A lack of tension can cause uneven layering, potentially affecting end product reliability. Operators need to recalibrate tension settings frequently. A well-documented tension control system can prevent these inconsistencies.

Lastly, wear and tear on machinery components can lead to unexpected breakdowns. Manufacturers recommend routine maintenance every 1,200 hours of operation, but many ignore this guideline. These overlooked maintenance checks can result in costly repairs. Keeping a detailed log of maintenance activities can help identify patterns and potential failures in advance. Understanding common issues is key to maximizing efficiency and minimizing downtime.

Best Practices for Maintenance and Longevity of the Machine

Maintaining a concentric stranding machine is crucial for its longevity and efficacy. Regular maintenance checks can prevent minor issues from escalating into major problems. According to industry reports, machines that undergo routine maintenance can operate 20% longer than those that don’t. This data emphasizes the importance of diligent upkeep.

Keep the machine clean and free from debris. Accumulated dust can hamper performance. Regularly inspect the bearings and replace them if they show signs of wear. It's a small task, but it can save costs in the long run. Machines often fail due to overlooked components. The average repair cost can be significant, with downtime affecting productivity.

Tip: Always follow the manufacturer’s guidelines for lubrication intervals. This simple practice can extend the machine’s operational life. Monitoring the tension in the strands during operation is essential. If it’s too high or too low, it may lead to malfunction. Track your machine’s performance metrics over time. It will help identify patterns and predict potential issues.

2026 How to Use a Concentric Stranding Machine Effectively? - Best Practices for Maintenance and Longevity of the Machine

| Practice |

Description |

Frequency |

Expected Outcome |

| Regular Cleaning |

Remove dust and debris from machine components. |

Daily |

Improved machine performance and reduced wear. |

| Lubrication |

Apply appropriate lubricants to moving parts. |

Weekly |

Decreased friction and extended machine life. |

| Component Inspection |

Check belts, rollers, and wiring for damage. |

Monthly |

Preventative maintenance and timely repairs. |

| Software Updates |

Ensure the machine software is up to date for optimal performance. |

Quarterly |

Improved functionality and efficiency. |

| Training |

Provide operators with training on machine operation and maintenance. |

Biannually |

Enhanced operator competency and machine utilization. |

Home

About Us

Products

Stranding & Bunching Machine

Extrusion Lines

Cable Packaging Machine

Automatic Cable Coil Strapping and Shrink Wrapping Machine

Automatic Cable Coiling and Wrapping Machine

Automatic Cable Coiling Machine with Microcomputer Control

Automatic Cable Spooling and Coiling Machine

Automatic Double Coiler

Cartesian Coordinate Palletizer

Circinate Film Cable Coil Automatic Packaging Machine

Film Heat Shrinking Machine

Robotic Palletizer

Auxiliary Equipment

Solution

News

Blog

Contact Us