Top 10 Tips for Choosing Automated Palletizing Equipment for Your Warehouse

Selecting the right Automated Palletizing Equipment is crucial for any warehouse. Experts highlight the importance of making informed choices. According to John Smith, a leader in warehouse automation, “The right equipment can boost productivity by 50%.”

When evaluating Automated Palletizing Equipment, it’s essential to consider your unique warehouse needs. Not all systems fit all environments. Size, speed, and load weight matter. Reflecting on past mistakes can guide better decisions. Many have chosen equipment that did not integrate well. This can lead to costly downtime and frustration.

It’s a journey of trial and error. The world of Automated Palletizing Equipment is vast and complex. Embrace your warehouse’s specific challenges. Properly assessing your options can unlock significant operational efficiency. As Smith emphasizes, aligning technology with your workflow is key. Make your selection a thoughtful process, not a hurried decision.

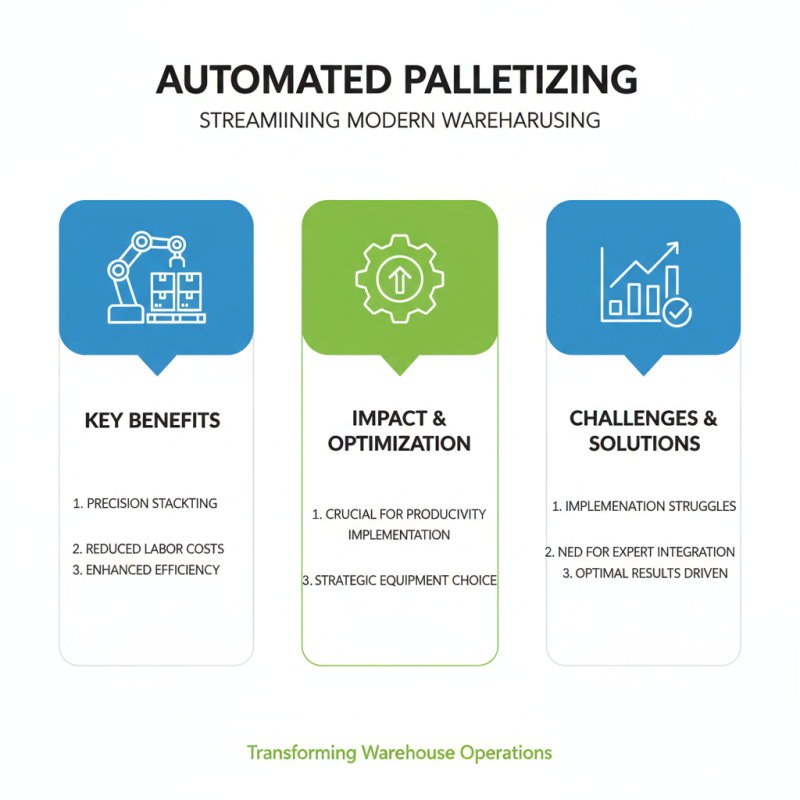

Understanding the Importance of Automated Palletizing in Warehousing

Automated palletizing has become crucial in modern warehousing. This technology streamlines the packing process. With precise stacking and reduced labor costs, it enhances efficiency. However, understanding its impact is essential for optimal results. Many warehouses struggle with implementing this equipment effectively. The right choice can dramatically change productivity levels.

Labor shortages drive the need for automation. Automated palletizers handle heavy loads without fatigue. They can run continuously, unlike human workers. However, some facilities ignore customization needs. Each warehouse is unique. Poorly chosen equipment may not fit specific operations. It's vital to assess your inventory types and layout carefully. Thorough analysis can lead to better decision-making.

Implementing automated systems is not a one-size-fits-all approach. Companies must consider the initial investment and ongoing maintenance costs. Sometimes, outdated machinery fails to integrate with new technology. Misalignment can lead to bottlenecks and increased downtime. Logistics and workflow must be at the forefront of planning. Avoiding these pitfalls can result in a more efficient operation.

Evaluating the Types of Automated Palletizing Equipment Available

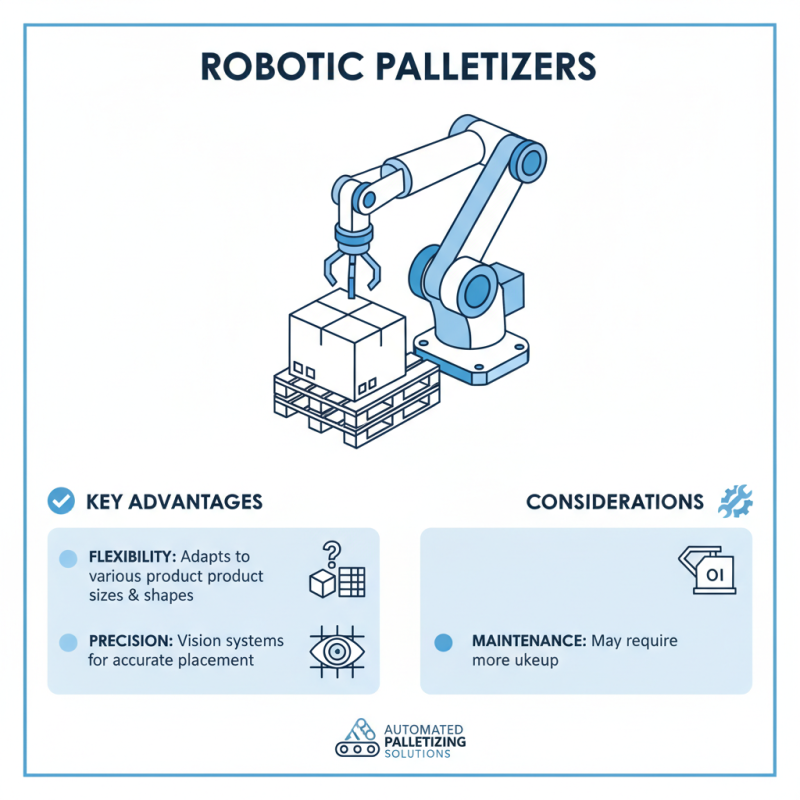

When evaluating automated palletizing equipment, various types come into play. Robotic palletizers are popular for their flexibility. They can handle different product sizes and shapes easily. These machines often use advanced vision systems to identify products. This helps in precise placement on pallets. However, they may require more maintenance.

In contrast, conventional palletizers are straightforward and reliable. They usually work with cases and bags, stacking them efficiently. Their design is durable, but they lack the adaptability of robots. You may find that changes in product lines demand more adjustments. The choice depends on your warehouse's specific needs.

Automatic stretch wrappers are another option. They help secure the load on pallets, preventing shifts during transport. While they may add throughput, they often need separate space. Consider integrating conveyor systems too. They can streamline the entire process but come with a higher initial cost. Reflect on the long-term benefits vs. the upfront investment. Choose carefully to suit your workflow.

Analyzing Throughput and Efficiency Metrics for Equipment Selection

When selecting automated palletizing equipment, throughput and efficiency are crucial metrics to consider. According to a recent industry report, optimized palletizing processes can increase overall efficiency by up to 25%. This significant improvement can lead to substantial cost savings. A thorough analysis of your current operations can unveil potential bottlenecks. Equipment with higher throughput rates helps meet increased demand without sacrificing quality.

Another key metric is the equipment's ability to adapt to varying load sizes and weights. Flexibility is critical in today’s rapidly changing market. Data indicates that warehouses with versatile palletizers reduce downtime by an average of 15%. However, it's essential not to overlook maintenance needs. Equipment that is more complex may require more frequent servicing, impacting operational efficiency.

Understanding your specific warehouse demands is vital. Metrics such as cycle time and energy consumption provide insight into performance. For instance, a recent survey revealed that 30% of warehouse managers overlook energy efficiency when choosing equipment. This can lead to higher operating costs. Striking a balance between initial investment and long-term savings is not always easy. Make sure you evaluate both aspects carefully.

Top 10 Tips for Choosing Automated Palletizing Equipment for Your Warehouse

| Criteria |

Description |

Metric |

Recommended Value |

| Throughput |

Amount of product that can be processed in a given time period. |

Units per hour |

200 - 1000 |

| Footprint |

Space required for the equipment installation. |

Square feet |

100 - 300 |

| Compatibility |

Ability to work with existing warehouse systems. |

Percentage |

>80% |

| Energy Efficiency |

Energy consumption during operation. |

kWh per hour |

< 5 |

| Maintenance |

Frequency and cost of required maintenance. |

Service calls per year |

1 - 2 |

| Ease of Use |

User-friendliness for operators. |

Rating (1-5) |

4 - 5 |

| Scalability |

Ability to scale operations as demand changes. |

Rating (1-5) |

4 - 5 |

| Safety Features |

Built-in safety measures to protect workers. |

Presence of safety systems |

Yes |

| Cost |

Total cost of equipment including installation. |

USD |

$50,000 - $150,000 |

| Lead Time |

Time from order to installation. |

Weeks |

6 - 12 |

Considering Space Requirements and Layout for Optimal Equipment Placement

When considering automated palletizing equipment, layout is crucial. A good design maximizes space and improves workflow. Think about the size of your warehouse. If it's small, choose compact machinery. Ensure there's room for maneuvering. Equipment should not obstruct routes for forklifts and personnel.

Tip: Always measure your available space. Use CAD software or simple sketches to visualize your setup. Consider high ceilings for vertical space utilization. Don’t forget about future expansion; your needs might change.

Another aspect is the placement of the equipment. Positioning can affect productivity. Keep palletizing machines close to loading docks for efficiency. This reduces the distance supply moves. Test various layouts before finalizing. It’s okay to adapt as you see what works best. Some configurations might seem ideal but become problematic in practice.

Tip: Be prepared to adjust your setup. Solicit feedback from team members. Their insight can identify potential obstacles. Investing time in planning will pay off in streamlined operations.

Assessing Total Cost of Ownership for Long-Term Investment Decisions

When considering automated palletizing equipment, assessing the total cost of ownership (TCO) is critical. This analysis goes beyond the initial purchase price. It factors in maintenance, energy consumption, and labor savings over time. A recent industry report indicated that energy costs alone can account for up to 30% of a facility's operating budget. Over several years, this can significantly impact the TCO.

Another important aspect is the return on investment (ROI). According to a study by the Material Handling Industry of America, many companies see a payback period of 24 to 30 months when implementing automated solutions. However, not all systems deliver the same efficiencies. Some might require more frequent maintenance or have hidden costs. A poorly chosen system can lead to operational downtime, affecting overall productivity.

It's essential to consider how the equipment aligns with your long-term goals. For example, can the system adapt to changing warehouse needs? Flexibility can enhance ROI. Additionally, companies should reflect on past equipment decisions. Did they truly consider TCO? Understanding previous oversights can inform better choices in automated palletizing solutions.

Automated Palletizing Equipment Cost Analysis

Home

About Us

Products

Stranding & Bunching Machine

Extrusion Lines

Cable Packaging Machine

Automatic Cable Coil Strapping and Shrink Wrapping Machine

Automatic Cable Coiling and Wrapping Machine

Automatic Cable Coiling Machine with Microcomputer Control

Automatic Cable Spooling and Coiling Machine

Automatic Double Coiler

Cartesian Coordinate Palletizer

Circinate Film Cable Coil Automatic Packaging Machine

Film Heat Shrinking Machine

Robotic Palletizer

Auxiliary Equipment

Solution

News

Blog

Contact Us